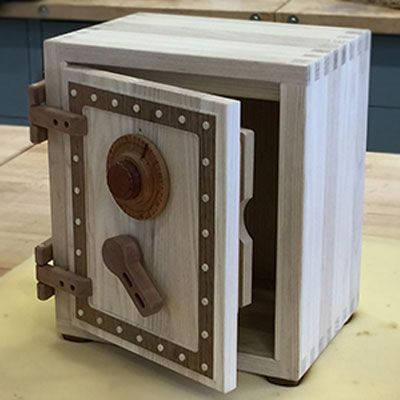

At the AWFS show in Las Vegas in July it was nice to see the familiar face of Bill Catmull. Bill is a long-time CNC advocate and is unusual in that he has both taught cabinet making and practised it professionally. However as he explains in the article it’s the teaching that he believes will be his real long-term legacy. One project he had worked on that really caught our eye was a wooden safe he had made using Aspire. He has not just made one of these but he’s also built them with the students at school and also taught the other teachers how to make them too! We asked Bill if he would mind giving us a brief history of what he’s been doing in and out of school and also show off some of his and his students excellent work.

I am an educator. I started teaching 42 years ago in one of nine high schools in Granite School District located in Salt Lake City, Utah. I taught 20 years in the wood shop. During that time people have told me I was somewhat progressive in my approach. I have been credited with being the first wood shop in Utah to make use of a computer; a Commodore Vic 20, a 64 then a Pet. I then moved to an IBM where I wrote programs in basic for school shop accounting, just two weeks ago I was talking with a retiring teacher who told me they were still using my software!. The Utah State Office of Education even sent me back to a national conference to make a presentation of what I had done.

After my time teaching I then spent 14 years as an administrator making every effort to keep teachers up to date on what industry wanted from the students we taught. During that time I personally purchased a ShopBot PRT96 that I just about wore out. To pay for it I had received an order for 12 solid redwood surf boards at $2,000 a piece.

Previous to Vectric being around I had become proficient in other CAD CAM programs and got to the point where I was teaching the teachers in the school district. The learning curve was a little steep for most of the teachers but we stuck with it and had some reasonable success.

Every June all the CTE teachers in the state meet for 3 days to learn new things and exchange ideas. I loaded my ShopBot on a trailer and pulled it 125 miles to that conference to hopefully fire up some interest in CNC. It worked but the hard part was getting the teachers to sell their administrators on the idea. As an administrator I placed ShopBots in every one of our high schools. It seems that every direction I turned I kept hearing "we don't need wood shops". Our director retired and he was replaced by one that did not have the same vision for what we were doing. At that point I retired with 34 years’ experience and everyone else in our department either retired or transferred to different districts.

I then started building kitchen cabinets full time. Using the CNC for some unique custom designs it didn't take long and I was booked out about a year on kitchens. I did that for five years and made a lot more income that I previously made teaching. The school district called several time wanting me to open up a new school. My response was not only no but *@!! no. Then one day as I was finishing up a $40,000 kitchen and sat back looking at it I thought to myself "In 20-30 years this kitchen will more than likely be replaced and I'll be gone and there will be no evidence that I was even here." The next time the school district called I said "OK" as I realized that after teaching students hopefully what they learn will in some way have an effect that carries on much longer.

I jumped into the most stressful teaching situation I had ever faced. It was a Title One school with close to 60% fee waivers and I knew I had to step up my game and start practicing what I had preached for so long.

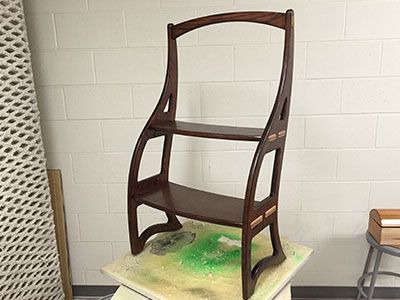

I made it a requirement that all students have exposure to the CNC. I had to keep the price of projects low yet keep the students engaged. That's when I developed the safe (It took me about 1 1/2 years and a number of not so successful versions.) along with a number or other projects such as longboard, lamp tables and tool boxes. The enrolment went up to where I don't have a free period and each year we have to turn students away. Both machines are running most of the time.

With that little success I was elected president of the cabinet making division of all the wood shop teachers in Utah. This past June at the conference I showed all the teachers how to make the safe and gave them all the files. Legacy brought two CNC machines down and I brought a laser engraver for the dials. In three days we pumped out 50 safes and none looked the same. There should be a number of the teachers that switch to Aspire because they really liked the safe and found Aspire easier that the software they currently use. The learning curve is critical with education as both students and teachers have very limited time to learn the software.

I am currently on a committee with the Utah State Office of Education that is re-writing the core curriculum for cabinet making that will require all teachers to include CNC training in their programs.

My school has also become the poster child for including composite manufacturing in regards to aerospace engineering training in high schools in two of the largest school districts in Utah. The companies include Boeing, Hexcel, ATK Orbital, Janicki and Harris and Company. Those guys have 5-axis machines larger than a lot of houses. There will be training in working carbon fiber and using CNC for cutting the parts.

We would like to take this opportunity to thank Bill for taking the time out from his workshop to write this inspirational article for us. To view more of Bill's work please scroll down to the small gallery below.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions