Have you ever wondered how you go from making simple house signs for family members, to creating a mammoth 8' x 16' tiled sign made out of 2" HDU as you can see to the right? So did we; that's why we got in touch with long time Aspire user Andy Brooks, founder of Brooks CNC Routing, to learn more about his passion for CNC.

In this case study we find out how Andy's commendable and fearless ambition saw him start a part-time, full-service CNC routing business which transformed into a full time venture… with multiple employees, multiple CNCs and a whole bunch of customers thrown in for good measure!

Within the discussion, Andy also tells us about the first time he discovered CNC technology, his use of both the hardware and software, and how he regards VCarve Pro and Aspire as tools that helped his business become as successful as it is today. We also showcase a number or projects that Andy tells us more about, including the giant sign we mentioned above. We start by learning more about Andy's career before setting up Brooks CNC…

"I first discovered CNC whilst I was working for a major window and door company. Initially, I worked on the plant floor back in 1985, and from there, I moved into IT work. Machinery, specifically woodworking machinery, has always fascinated me, and I found it exhilarating to see the results you could get just by passing raw material through these CNC machines. The company had several of them, and I set my sights on obtaining my own."

"Since then, I have worked in IT for a total of 27 years, with 5 ½ years in phone support for a major software company and 21 ½ years in Desktop Support. The latest Desktop Support IT job was with Northeast Georgia Medical Center for a bit over 6 years while building my CNC business on the side. I began offering CNC services in 2005 shortly after purchasing my first CNC machine. !"

"Like many entrepreneurs first starting out, my business headquarters was the good 'ol garage, and my wife dubbed the noisy contraption her new car. Offering full-service CNC routing, I was not daunted to take on any job. That fact is still true and sets me apart from my local CNC companions. Initially, I mostly cut doors and drawers for cabinet shops in the area which eventually led me to my first shop. In 2006 I started renting a 14' x 14' area in a cabinet shop I had been cutting for. Still working in IT full-time and CNC only at night and on weekends, I gradually added customers here and there. Through word of mouth and long hours, my customer base grew too large for me to handle alone; I needed help, and in July 2011 I hired my first employee. I would draw the designs at night, and he would run the CNC while I worked full days in IT at the hospital. With business growing and more work coming in each week, I decided to build a shop behind my home in August 2012. Just four short months later, I took the plunge for good and dedicated 100% of my time to the CNC business. My New Year's resolution was underway as of December 28th when I turned in my notice to the hospital. I knew this wouldn't be like any other weight loss kick that wanes after February. This was do or die… well, perhaps not that severe, but it was going to be the only butter for my family's bread – and the bread for that matter. Shortly after the New Year I started working on purchasing my second CNC. It seemed that my efforts to build my own personal shop came just in the nick of time. Due to bad economic times, the cabinet shop I rented space from needed to amalgamate with another cabinetmaker to reduce overhead. This translated to my business being pushed out. I would need to move both of my CNC machines into my personal shop, but within a mere few weeks before I could even begin moving into my shop, it was apparent that I had already outgrown it. I needed space for two CNC machines and all of the new material continually coming in. I was blessed by October to find a 2700 square foot building only a mile and a half from home, and by the second week of October, I officially moved in. By this time, I had two employees, two CNC machines, and so many ideas swirling around in my head about this new endeavour. Currently, I work with a craft show customer, sign shops, exhibit companies, cabinet shops, a molding company, a fitness company, an entertainment company and a couple of marketing and design companies."

"During the first several years working the business part-time, I found it challenging to obtain new clientele. In the first few months, I sent out 100+ letters introducing myself and the services that I offer to cabinet shops within 25 miles of my home. Of all the letters that I sent, I only received one phone call. Ironically, that one call was from a high-end cabinet shop that I reluctantly sent the letter to due to the high-end work they did. After all, I was just the guy working out of his garage. That phone call was for the custom curved molding, the first paying job that I had on my CNC."

"For visual advertising, I purchased magnetic signs and later vinyl signs which I applied to my truck. As the saying goes, word of mouth is your best advertising, and until recently, word of mouth has been just that. A job well done for one customer will always lead to more work."

"However, today my best advertising tactics are my website and Google AdWords. A good website with a supple amount of past project photos is crucial. Currently, my website is getting a facelift and will look better than ever upon completion. "Through web-based advertising, I have been able to work on projects for customers in New York, California, Florida, Kentucky, Tennessee and Texas."

After talking to Andy about how he setup and continues to grow his business, we were keen to find out what equipment he is currently using to help him deal with the high demand for his services…

"When it comes to CNC equipment I currently own a Shopbot PRTAlpha96 with a 5hp Colombo spindle originally purchased in 2005. Recently, I added a Shopbot hybrid to the shop. It is a 5" x 10" with a CNC Router Parts table and a Shopbot controller."

"In terms of software, I use Vectric Aspire. I remember being at a Shopbot Camp in 2006 and a gentlemen called Bill Palumbo, a representative from Shopbot, told the camp attendees about a new company called Vectric. Initially I purchased VCarve Pro when it first became available, and since then, I upgraded to Aspire never looking back."

"Not only would I say that the Vectric software has benefitted my creations, Vectric software has helped me create my business. The software that came with my CNC was very limited in its applications. For example, if I needed something special cut I would have to pay to have the file created in a CAD/CAM package which I could not afford. Unable to see the way the file would cut on my machine was like rolling the dice; I could only hope that it was right. From the first time I used VCarve Pro I fell in love with the software. Not only was it incredibly easy to use, it allowed me to create the cut files myself and see the way the file would cut before I ran it on my CNC. On top of that, VCarve Pro allowed me to send a picture of the file to be cut to the customer before I cut it on the CNC which saved my customer and me time and money. It allowed the customer to see what they were paying for before they gave the approval. Consequently, one of the very first jobs I utilized this feature for, the customer noticed the file needed to be modified with minor changes to the text size. Prior to using VCarve Pro I could have easily wasted material before realizing the size discrepancy. Just the feature of being able to add 3D components to my creations has paid for the software in itself three times over."

"Ultimately, with the release of Aspire, my business has been taken to a whole new level. I purchased the first version of Aspire shortly after its release. Now I am able to create my own 3D files and modify any pre-existing files I already had. I have generated several small 3D components which I add to cabinet doors and other cabinet parts. These small features have separated me from my competition."

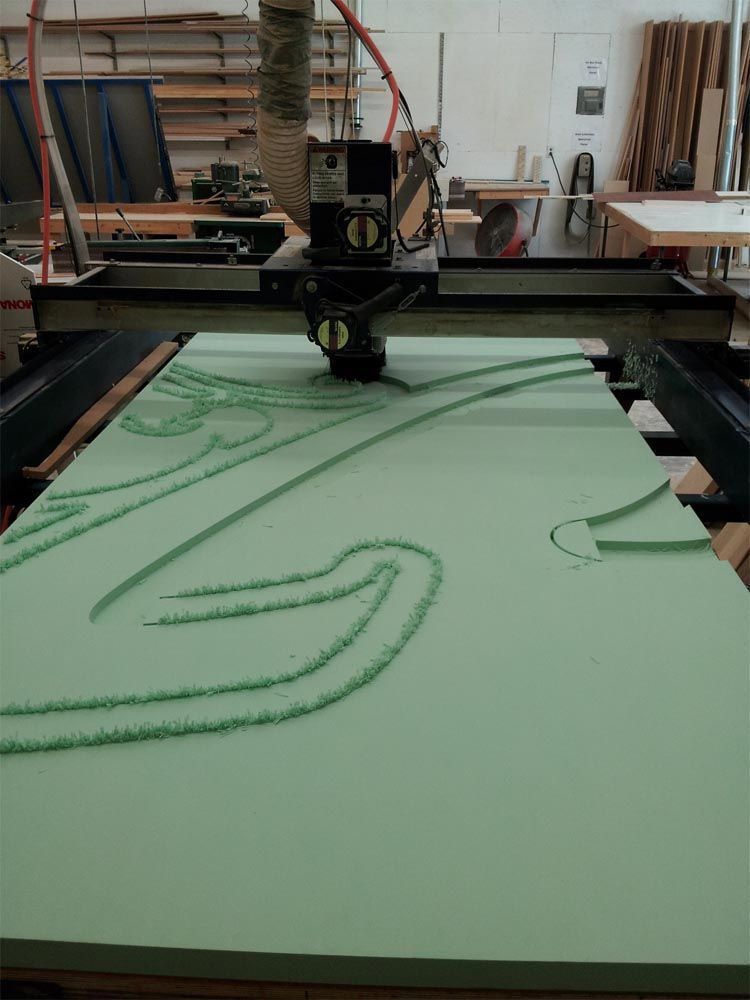

"Toolpath tiling is another feature that has benefitted me greatly. I was contacted by a local sports apparel company and asked if I cut signs. Naturally my answer, yes, and they needed a sign for their new facility. The sign was to be 8' tall by 16' long with three separate depths of pocketed areas within the logo. I was able to create the sign in full size and use the Toolpath Tiling to break the toolpaths into sizes that would fit onto my 4' x 8' table. After cutting the four panels the signs were delivered to the customer for painting and installation. As a result of the toolpath tiling, my customer was amazed that the sign went together seamlessly. You can read more about this project further below."

"My two favorite time-saving features of Aspire are the Layers and Toolpath Templates. Another customer of mine sends me DXF files that have individual sheets in one file. Occasionally, the file contains up to 73 individual sheets that need to be toolpathed. Before discovering layers and the toolpath templates, I had to create the toolpaths separately for each sheet. As you can imagine, creating toolpaths for 73 sheets takes hours. Fortunately, with the toolpath templates I can copy the vectors into a new file and center them on the sheet. I simply load the template, and the template adds the missing layers and toolpaths. I then verify that the vectors are on the correct layer and select the Recalculate All Toolpath icon. In a matter of a couple of hours instead of several, I save the toolpaths to cut and move on to the next project."

"I remember that after setting up my first CNC I started making house signs for family members. My first paid for job using my CNC was a project that required me to match some pre-existing vintage custom curved molding. This was used to frame-out a mirror to be placed in a multi-million dollar home's bar."

For the final part of this case study we look at a four of Andy's completed projects and some of the key features that helped him complete them.

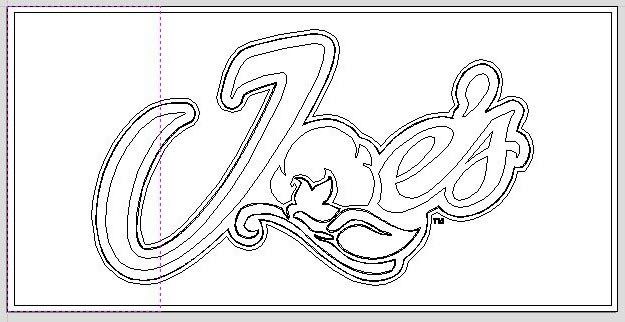

Joe's Sign

"This sign was created for a local sports apparel company who specified that they wanted the design to be three different depths. The material used was 2" HDU and the green painted area is pocketed down ¼", the white area is down ½" and the blue area is down ¾". The design and finishing was done by the customer."

"This job would have been very difficult to piece together without the 'Toolpath Tiling' feature in Aspire. With this job I found that the Vectric forum was a great resource. Tim Merrill, forum user 'tmerrill', has a great 'how-to' guide on Toolpath Tiling. After reading this I was able to create the toolpaths in about 15 minutes."

"You can see Tim's forum post here:

http://forum.vectric.com/viewtopic.php?f=2&t=14793&p=102807&hilit=Tile+toolpath#p102807 "

Whitmire Closet 3D Carving

"The cabinets were for a personal home of a large home builder in our area. My customer, Covenant Woodworks, has provided the closet cabinets for several homes he has built. My customer wanted to add something special to his customer's wife's closet. He came up with a concept and asked if I could design something. The flourishes were from the Vector Art 3D collection with some minor changes/additions to them. The medallion was created totally using the Aspire software. I combined all the components in a dished area like the Vector Art 3D B styles. The design was then carved into door grade MDF."

"Vectric software was a great help as it helped me add, edit and create all of the 3D components. With this project I found that creating simple 3D components is actually a lot of fun. With a little thought you can create your own components and start your own collection of models."

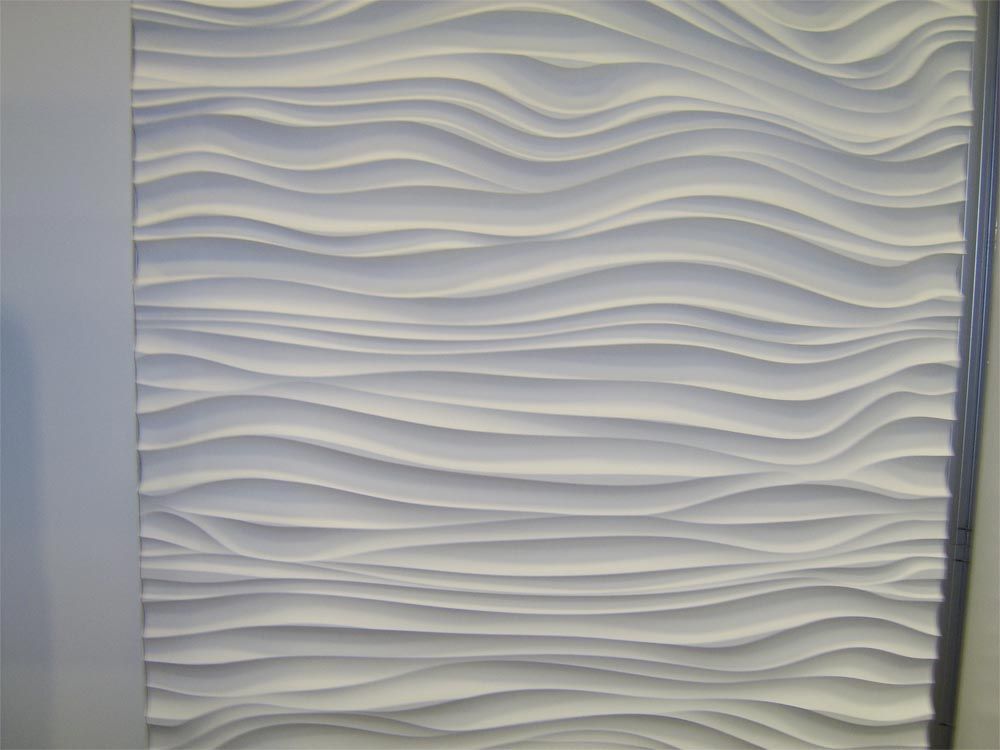

Ripple Panels

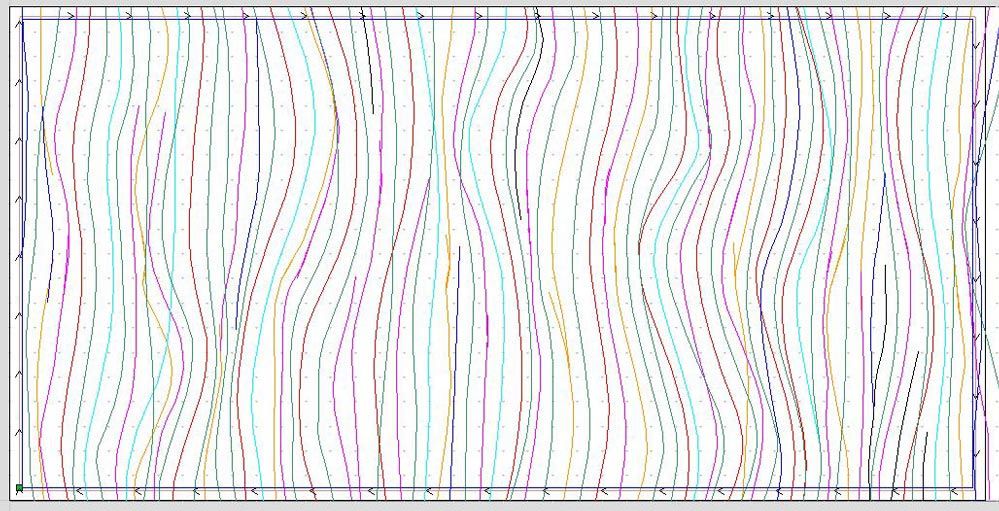

"These ripple panels were created for a trade exhibit company. After talking with the customer and understanding what he was looking for I was focused on creating a 3D file. Eventually it was cut using 2" ball-nose bit with a series of well-placed lines all done with 2.5D toolpathing. Fluting played a major part in creating the toolpaths for this project."

"Initially I found myself wrestling with this piece for a while and visiting my customer's location a couple of times to look at his existing panel, I eventually realized that I was over thinking the concept. All along I had been trying to use 3D toolpathing. After figuring out how I could use vectors and the fluting toolpath I was able to cut a 3' x 10' panel in about an hour. If I had used a 3D toolpath the cut time would have been well over 5 hours!"

Deer Site Cabinet

"This was another project for the same company I did the closet carving for above, Covenant Woodworks. The design in the centre of the piece was from the Vector Art 3D collection using the style 'B'. This project was very simple and proved how easy is really is to add 3D components with Aspire software and go straight onto generating the toolpaths."

We were delighted to see how Andy is using Vectric software to create such fantastic pieces with his CNC's. To finish, we asked Andy what he is working on next…

"I love new challenges, and my customers do not disappoint me. As a result, I have been able to work on some very interesting projects."

"Recently, I finished cutting designs that will be applied to headboards of a hotel in the New England area of the United States. The client originally ordered 220 pieces, but by completion, the order was for over 260 pieces."

"I am currently working on projects that I would love to tell you about. However, the projects are for some high-end clients, and I am unable to disclose any news about them at this time. They will use features in Aspire though so stay tuned to the Vectric forum, I can't wait to tell you about them! I will say this however; the new project is made possible with Aspire, and it will be my most exciting work to date!"

If you would like to learn more about Andy or would like to make contact with him, then you can learn more about his business via his website: www.brookscnc.com. Alternatively you can find more info and ask questions in existing threads over on the Vectric Forum where you can find Andy by looking out for user 'andyb'.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions