Caleb Dawson is a product designer who has been using Cut3D and VCarve Pro for 2 years and 3 years respectively to help create three-dimensional prototypes of his consumer and furniture designs.

Caleb has found both pieces of Vectric software invaluable for speeding up the design process and shaving costs off getting his designs prototyped.

“I'm not a professional model maker but VCarve Pro and Cut3D’s ease of use allows me to carry out the prototyping work myself that I would otherwise have to pay somebody else to do. It saves me money and time.”

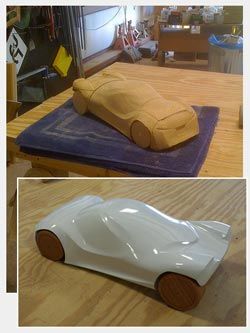

One of Caleb’s most fun Cut3D projects was the Model Car shown here. Designed on paper in 2004 for the Peugeot design contest, Caleb decided it was time the design was seen in full 3D, even if was at 1:8 Scale.

Caleb Describes the process he went through to use Cut3D to machine and finish the prototype model:

"The initial 3D car Model was built in a separate 3D Modeling software package called Rhino CAD software. I then used VCarve to generate toolpaths for the structural parts on the inside of the model.

Next, within the 3D CAD modeling software, I exploded the exterior surfaces of the design in several parts that were small enough to machine individually on my router, setting up the individual parts for machining by orienting them so they would fit on the router. I modelled borders and tabs that would work with the 5/8" particle board and the router bits I was planning to use to build the model.

I exported these parts as STL files and opened them in Cut3D. I set up the roughing and finishing toolpaths for each part and started machining".

The parts fit together reasonably well but, as Celab chose to use a relatively cheap particle board to keep costs down there was still a lot of finishing required. Before achieving the finished car model seen top right.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

GB115123072

Privacy Policy |

Terms and Conditions