This month we turn our attention to Aspire user Terry Mould. Now based in South Wales, Terry has retired from work as an engineer and has taken up working with his CNC as his main hobby. With over 40 years of experience creating projects using CAD software and many other different tools, we were interested how Terry got into CNC machining as a pastime and how that fits into his retirement...

I have now retired from full time work and live in Monmouth South Wales but I still go into companies and train employees and apprentices in engineering subjects from machining skills to CAD drawing, lean techniques to welding when required. My last full time job was as the manager of a machine shop that trained people away from their own factory in all forms of engineering. To make it interesting we used to sometimes design and make robots to appear in TV programs, the legs of the last project that was never completed stands on my desk, waiting…

I first got interested in CNC machines in the late 70’s when home computers were very new and strange, to program a CNC machine to work required many hours working out coordinates and intersections with the aid of trigonometry and a calculator before typing it by hand into the machine, we have come a long way from that to the modern Vectric software which allow the user to produce amazing items with no knowledge of programming in a fraction of the time.

With more spare time, the idea of returning to the world of CNC grew, I researched all the current software and watched loads of YouTube clips before deciding to get Aspire. I quickly realised that the only limit to what could be designed was down to my efforts and imagination. Until recently I owned a small but fully equipped engineering workshop in which I created metal sculptures to order (image to right), but a move to a new house, that I have just finished, prompted a downsize to a more modest size workshop, and a change in focus from steel to wood.

As a first dip of the toe in the world of CNC routers I have a small UK built machine with a table cutting size of around 12 inches square but am busy designing a larger replacement, now the bug has full hold and the idea of larger projects mount up as well as the need for a larger machine.

The one addition I am planning to the present machine is a 4th axis. This will allow me to make some replacement rings and parts for the ‘Cryptex’ device (right) designed and built after reading Dan Brown’s book ‘The Davinci Code’. I have already been looking at Youtube clips of the rotary work done with Aspire and know it will enable me to design and make more highly patterned parts with greater ease.

I am still learning everything that Aspire can do and how to do it better so each time I design a new model I try to see if I can improve my workflow. The freedom that Aspire gives the user means there are always different ways to create and design, plus I have found it to be a very robust piece of software. I am a MAC user, so I run Aspire though an emulator and have never had any issues with speed loss or crashes, I can also produce the Gcode that Mach3 uses on the CNC machine without need for any changes or problems.

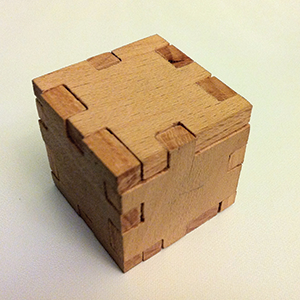

I was recently ask by a friend to make a 3D puzzle cube with all 6 sides being unique. For this project I was able to draw the parts in CAD, import them, use Aspire to add dog bone corners and lay them out on the cutting sheet with a cutting allowance which meant that only a small amount of cleaning up was needed on the hold down tabs before all the parts could be assembled.

Introducing Aspire seemlessly into his workflow, has allowed Terry to save time and material waste. Now, with his CNC in full flow he has been very active on the Vectric Forum. We recently came across one of Terry’s many posts in the Aspire Gallery Section. With an unusual concept in hand, we were keen to ask Terry how he came up with the idea to create “Stair Creatures”…

The materials for the creatures in my most recent project came from a friend, the darker wood was once desks in a school science lab, while the paler wood came to me as oak doors from a kitchen, but turned out to be pine, the idea behind it came after finishing the stairs in my new house and thinking it would be good fun for my younger visitors to be able to find some creatures between the spindles and on the newel posts as they went up and down.

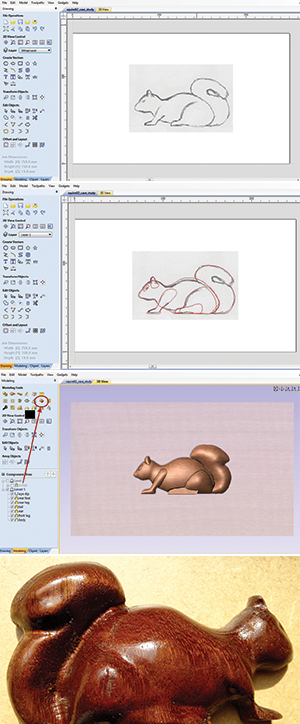

Each one started the same way, with a simple sketch, this was imported into Aspire and used to create vectors and act as a visual reference. I used a horizontal guide line to ensure the bottom of the model would be flat and so it can stand up when finished.

First the outside main shape then the detail parts like legs, tail and ears, these are converted into basic shapes, I always think of where the parts of the model will blend, like the base of the ear and the shoulder on the legs, these I draw past my reference sketch so I can sculpt and shape them later.

Tilting and sizing as required to make a rough basic model, at this stage I use the ‘create components from visible model’ option to use for modeling without the need for me to group and copy a backup of the parts, this I move to a new layer for the detailed work, now I can return to this stage and try different sculpt version’s, before working out the tool paths and cutting the part on the machine

Sometimes I find it best to use a digital pad and pen for sculpting but generally I use a mouse. When I am happy with the sculpting stage, which can take a while, it is over to toolpathing, this model was roughed with a 6mm (~1/4 inch) endmill then finished with a 3mm (~1/8 inch) ballnose. The final cutout profile was done with a 4mm (~5/32 inch) cutter leaving a few tabs to keep it in place. This shows the right side of the pair after machining and a gentle clean up followed by a coat of spray varnish.

To further my skills with the software I attended the first UK Vectric User Group Meeting last year and would highly recommend it to anyone who would like the chance to talk to other users, see examples of work and speak to the people behind the software. As for me and my workshop, there are many projects in the pipeline for the future, a new 3D puzzle, but this time based on a hexagon shape using the dovetail gadget for some of the joints, a small frog to join the rest of the stair creatures, a plaque for a local rugby team, the Cryptex and more.

We would like to take this opportunity to thank Terry for his time in answering questions for this article. You can see a small selection of other projects below and register on the Vectric User Forum to see his future posts.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions