Three years ago at the age of 60, Tom Freeman retired from a career as a software engineer, manager and executive. Tom had enjoyed and benefited from many years of high-risk/high-reward start-ups, 60 hour work weeks, building great teams, products and navigating corporate politics. However, his real passion pointed in a different direction... artisanship. Tom had always enjoyed designing and producing beautiful, high quality objects from wood, metal, stone, etc. which he and others could incorporate into their home and business environments and enjoy for a lifetime.

Since most of the work stock used by eWoodArt is relatively small e.g. wine barrel parts, the CNC machine can also be relatively small, in this case a ShopBot "Buddy" with a compact 24" by 32" table. When producing custom products the company faced challenges such as having to develop a suitable hold-down system and effective dust collection solution for unconventional material sizes i.e. curved oak barrel staves. Tom describes his method for overcoming these problems.

Hold-down Strategy:

"One of the keys to working efficiently and safely with CNC equipment is developing an optimal work-piece hold-down strategy. There is no single best solution given the huge variety of possible types, sizes and shapes of stock and finished product. For us the most common stock pieces are 18-24" round by 1" thick oak barrel heads and 24-35" long by 3-5" wide curved oak barrel staves. We experimented with a variety of hold down fixtures and jigs and finally settled on a T-Track system with the track screwed down into routed out channels radiating out from the center of a plywood base. The work stock is held down with aluminum hold-down clamps that ride in the T-Track (all available from Rockler). Even warped barrel heads can be held down tightly and securely by attaching 4 to 6 hold down clamps around the perimeter as shown in the photo ( below right).

The clamps are positioned at the outer tapered edge of the heads so that the entire flat surface of the head can be milled flat with a circular tool path, this ensure there is no interference from the clamps. We hold down curved staves and other pieces by drilling holes in waste areas of the piece and screwing them down onto a sacrificial backing that we then clamp to the T-Track base. Because the rails and hold down clamps are aluminum, it is not a disaster if we accidently hit them when carving."

Dust Collection Solution:

Tom goes on to describe his dust collection solution that works well with his hold-down strategy, which is partially facilitated by the compact size of the CNC machine.

"We also experimented with a variety of dust collection strategies before coming up with one that works really well for us. Solutions that involve a vacuum shroud around the cutting tool (such as the accessory that came with the ShopBot) were simply not workable. The shroud interfered with our hold down system and severely limited operator access and visibility of the cutting area. We considered building a small air-tight "booth" for the machine inside our shop with a powerful exhaust fan (much like a paint spray booth) however the operator would still have to work inside this environment and be constantly exposed to a great deal of dust and noise. We eventually realized we could shrink the size of the "booth" down to a box just big enough to enclose the machine and build it on and around the steel framework of the ShopBot. It required careful design and planning to ensure this box would not interfere with any possible movement of the machine or the work pieces on it. It needed to have a hood that could be easily opened, closed and removed when necessary. It needed transparent windows so the operator could see what's going on and have removable panels for clean out and maintenance. Finally it needed a dust collection port that could be connected to an exterior dust collector, in this case a dedicated Shop Fox 1500 CFM unit.

The photo to the left shows the dust collection "box" mounted on the ShopBot. It is framed with 2x4 and 2x2 fir bolted onto the ShopBot steel frame and covered with ¼" white melamine and 3 large plexi-glass windows, which completely envelop the machine except for a couple inches around the bottom where air is drawn in. Lighter dust is drawn up and out the port in the back, while heavier dust and chips fall to the floor inside. Recognizing the build-up of chips and dust is a fire hazard we regularly clean it out by opening the hood and removable side panels, and sweeping it out. Other benefits of this solution are that ambient noise is greatly reduced, as is the danger of "shrapnel" being thrown into the shop."

Stave Signs are another customizable eWoodArt product. Here Tom describes some of the unique aspects involved with this type of production,

"We also offer custom signs and decorative plaques made from the curved side staves of barrels. We have not seen anything quite like ours in the market, probably because its fairly difficult to accurately produce carvings on a complex 3D curved surface at a relatively low price!

In this example I use our company logo stave sign as an example. It is carved on an extra wide 5" stave and includes intricate hand painting.

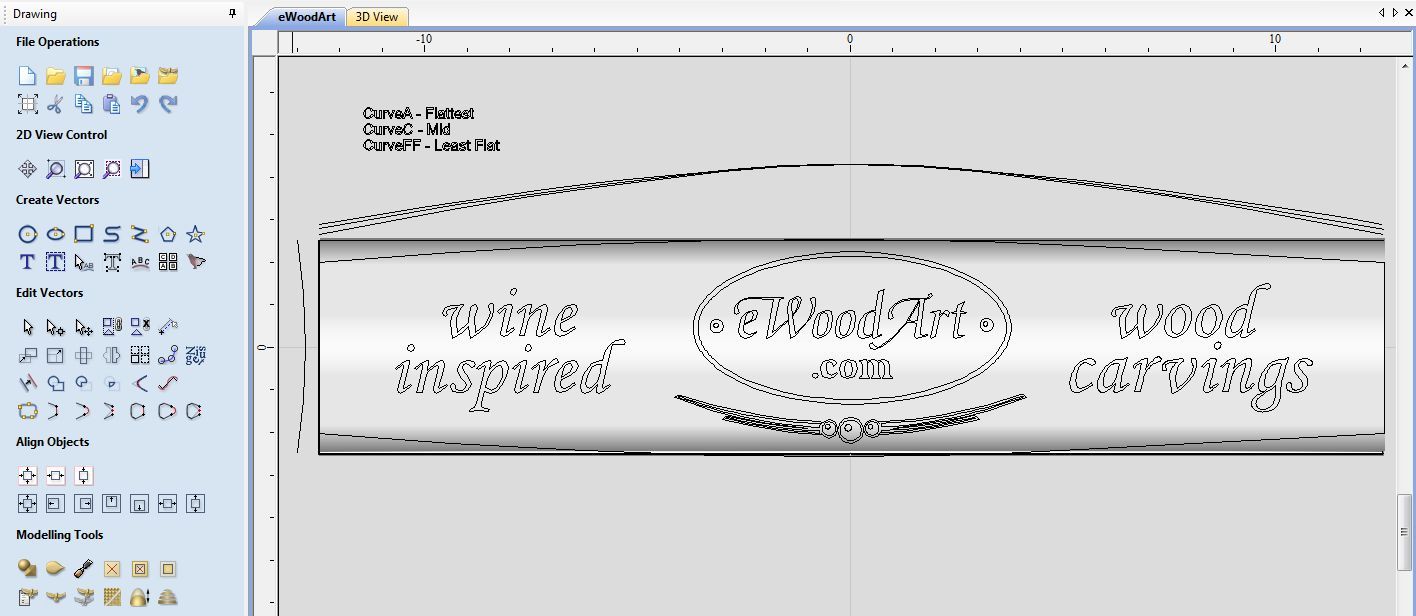

Here we leverage one of Aspire's most useful and elegant features: the ability to easily model a wide variety of complex 3D surfaces with the 2-rail sweep feature, coupled with the capability to project a design onto that surface.

We measure a stave's curvature along both its length and width, produce vectors for these curves and then use the 2-rail sweep to create the model. The screen shot below shows the required vectors in Aspire, including several stave length curves on top and width curves on the left. These can be used for the 2-rail sweep. Also shown are the stave outline and the carving vectors.

This next screen shot shows the "preview image" resulting from the 2 rail sweep with the V-Carved logo and text projected onto it.

One challenge with barrel staves is that they are fairly complex curves within 3D space, but the even bigger challenge is that no 2 staves have exactly the same curvature, even those from the same barrel! Even a small divergence of stave curvature from an ideal model can result in an inaccurate and flawed carving.

It would be far too expensive to individually model each stave's curvature and feed that into the production process. Our "secret" to resolving this is to generate a number of stave curvature model variants, from which we carve "curvature templates" out of plywood. We then fit each prospective stave blank against a set of these plywood templates and sort them into bins of known curvatures.

Unless otherwise requested we sand the carved stave down to clean new oak and apply painting, stains and topcoats. The stave is then finish sanded, removing any over-paint and leaving the recessed paint in the carved out areas. The stain is applied and where needed, paint is applied to the high surfaces of the carving.

The final step is to add the hanging or mounting hardware desired by the customer. The end result of all this work is a stunning piece of custom wood art that goes way beyond the look and feel of an ordinary flat sign."

We wanted to know what interesting products eWoodArt are currently working on and what markets the company are hoping to expand into. Tom goes on to describe some of the interesting projects the company have currently taken on within the hospitality industry, a sector they are very enthusiastic about.

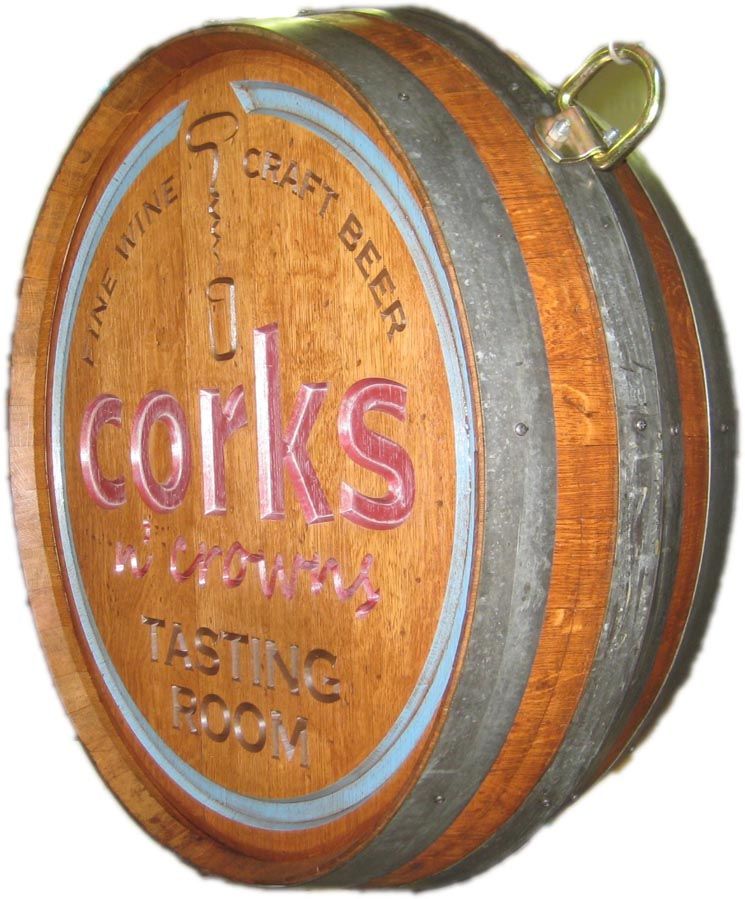

"Serving the hospitality industry i.e. interior designers and architects of hotels, big restaurants and bars, etc. was not initially on our radar, however our unique focus on wine inspired wood art and our growing gallery of wine decor eventually caught the attention of a few early adopters in this industry. First we were commissioned by a few large bars and tasting rooms to make double sided barrel signs, basically two "tenth barrel head carvings" attached back to back that could be hung over a door and seen when approaching from either direction, as demonstrated in the image to the right. This product is a large 32" diameter double sided sign made from a large "puncheon barrel" for Corks & Crowns wine bar in Santa Barbara. The owners also wanted the sign to look 100 years old like the old wine bar building itself. We learned a lot here on how to use tools and apply various finishing techniques for distressing and ageing the wood.

On another occasion an interior design firm approached us with the concept of doing a barrel "pyramid stack" for a new big steak house in Dallas. This project is essentially 30 individual "tenth barrel carvings" carved with the logos of some of their major wine suppliers. These were arranged in a pyramid shape to suggest the way barrels were originally stacked in wineries before the days of steel racks and forklifts. The finished piece can be seen in the picture below.

That project then led to another high-end restaurant chain reaching out to us for another big "wine feature" to act as a focal point for their new restaurant in Las Vegas. They wanted three, 5 foot diameter wine tank heads, to be mounted within stone archways to greet their patrons in the bar. The tank heads needed to be carved with authentic modern day winery logos, but also look like they were just removed from a 100+ year old working winery, complete with red wine stains and other distressing and ageing. We built these from scratch ourselves since old used oak wine tanks are rarely available and modern wine tank builders make only whole tanks and are not in the business of making them like they were made 100 years ago.

We gathered lots of pictures of authentic old tanks and went about designing ours. The customer loved the massive look of the heavy oak beam cross braces, the clean out knockout and its brace and iron "wing nut" tensioners we had fabricated (as seen above). The real antique tasting spigots that we found online added a lot of authenticity. The owners were thrilled with the final look and feel.

So, after some very successful hospitality projects, its clear that we've found a promising new direction for the business. As a result we plan to market to the hospitality industry much more aggressively, while continuing to build on our base product offerings."

You can follow the very latest updates from eWoodArt at their website www.eWoodArt.com where you can also subscribe to their monthly newsletter and follow them on a variety of social networks including Facebook and Twitter.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions