This month we talked with Michael Mezalick of Mezalick Design Studio, LLC and its subdivision CarvedDetails.com. He shared with us his experiences with CNC how he has learned the Vectric software and the diverse range of projects that he and his team (pictured right) have worked on.

Michael started by going into detail about his lifelong passion for design and architecture. He explains how his career in this field prompted him to start utilizing CNC technology to secure jobs that required accurate repeated detail that would be difficult to achieve by hand. Michael also showcases a number of inspiring projects that he and his team have completed or are currently working on, and talks about how Vectric software has helped support his latest business venture that offers dimensional design and file creation services to other companies.

"I came into the world of CNC in a different way than you might expect.

At the age of 10, I knew that I wanted to be an Architect, so I spent the better half of my early years studying so that I could achieve this dream. I've always been passionate about design work, everything from Halloween costumes and Christmas decorations to stage sets and Parade floats, these were my "hobbies" as a young boy. I even started working for an Architect at high school!"

"If you have seen any of my work before then you may have noticed that I am very passionate about stained glass. This fascination began whilst I was studying music at the University of Cork, Ireland for a summer semester. It was there that my eyes were opened to the beautiful architecture and amazing stained glass that complimented so many buildings. As soon as I returned to the U.S., I immediately started to learn more about glass work production and in 1972 opened a small studio where I made gifts for relatives and area gift shops."

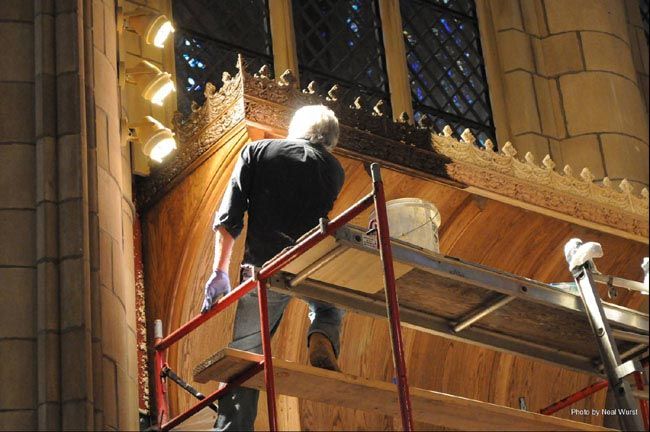

"Over the years my business has expanded, especially within the North East region of the U.S. which surrounded us with an almost endless array of buildings with very ornate decorative elements. Many of these were in dire need of maintenance that require skills in wood carving, mosaics, gold leafing and ornamental plasterwork, all skills that I managed to develop over time. Over the past 40+ years, I have worked mostly in religious buildings of all denominations, covering almost every state, while the requests from clients has also taken us to several foreign countries."

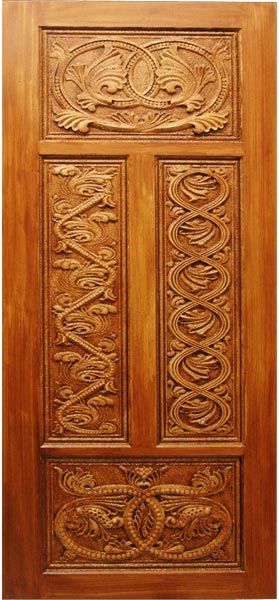

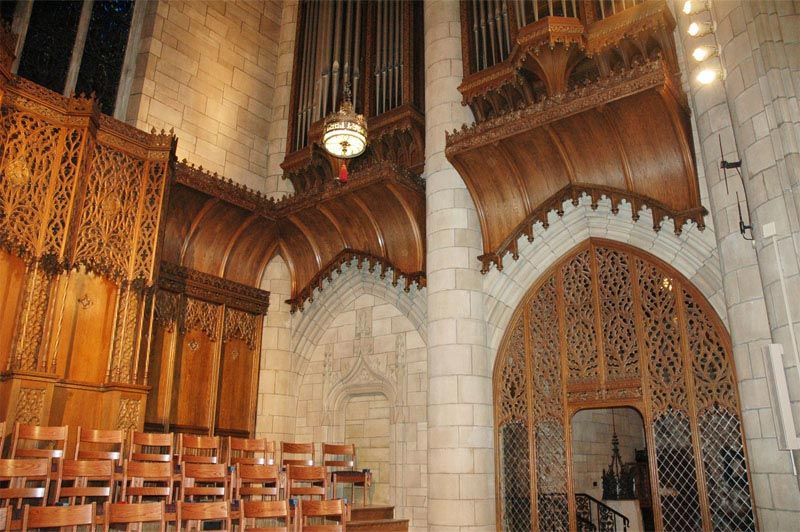

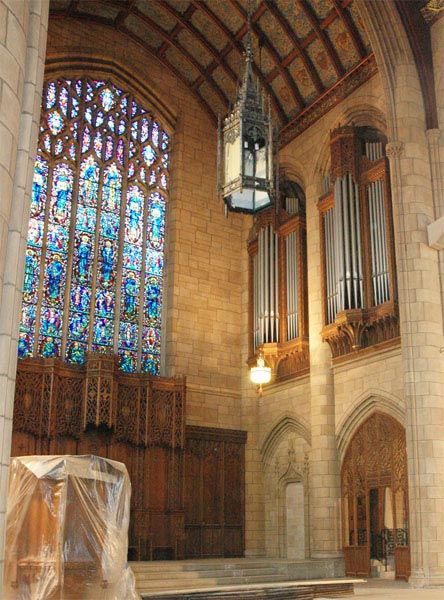

"A few years ago we were commissioned to restore the stained glass windows of a large Gothic church in Erie, PA. This unique type of building, not often seen in the US, was constructed in 1929 but is reminiscent of the great cathedrals of Europe. While on-site we were offered the opportunity to design several large wooden structures for the sanctuary area that would enhance the sound quality of the choir."

"The directive of "making it look original" meant designing with the mindset of the great craftsmen of the early 1900's who understood the geometry and subtleties of the 15th century. This design idea won the unanimous approval of the project board and the members of the congregation. This is when we had to start thinking about how we were going to fabricate what I saw in my mind's eye whilst keeping to the tight budget and time constraints!"

"Hand carved moulding played a big part in this project, blending the old and the new, but the cost of duplicating such work with hammer and chisel was prohibitive. It was at this time that a friend suggested using an automated carving type system. This was when I first discovered the world of CNC machining."

Michael goes on to explain how he developed his skills and knowledge in Aspire enabling him to create projects to satisfy him and his customers high standards…"It wasn't long after learning more about CNC that I decided to purchase a Shark Pro, (Dec, 2008), and with the guidance of Brady Watson (of iBILD) who did the first scanning of an original section of moulding, I took this chance to learn all that I could about CNC work. Vectric's VCarve Pro software came with the CNC machine and I'm pleased that it did. I had no time for a steep learning curve and Vectric's program fitted perfectly with my tight schedule. The project turned out to be a huge success."

"I can say that I am truly a poster child of the "plug and play" generation, but Vectric, and its multitude of members on the forum helped with anything I was unsure about when it came to technical and engineering knowledge surrounding CNC."

"I grasp every opportunity I can to learn more about the technology and reading the Vectric forum on a daily basis opened many doors for me. Whilst browsing the forum I heard about the first "Camp V-Carve" (2009) at Jim McGrew's (of James McGrew Cabinetmakers) workshop which I went on to attend. I also attended the Vectric User Group Meeting in Pittsburgh where I saw firsthand the inspired works of other craftsmen. This is when I realized the potential of CNC and that I was unable to take full advantage of the technology with the small machine I had. After much research I chose to purchase a larger CNC machine from CAMaster which I have since customized for our needs. I also purchased Vectric's flagship software package Aspire to take my business to a whole new level."

"I would not have been able to have developed as far, nor as fast, as I think I have, if it was not for the Vectric programs. I have since taken some time to start using other design programs but their steep learning curve would have stunted my forward movement in the world of dimensional work.

Aspire is an elegantly intuitive program with graphics and displays that the average person can easily grasp. I use it as the foundation for all of our dimensional modeling work.

"As a hands-on type of designer, the sculpting tools in Aspire strike a very comfortable ring for me. Working in what may be considered an old world mentality, most of our work does not afford me the education of CNC and other machine type work. Aspire allows me the ability to design anywhere I go but to still create pieces that will have the finish of a hand crafted item. I look closer now at works that I admire and think of how that can be created using any of the Vectric products. After realizing that the dimensional side of the Aspire program is similar to modelling clay, with its blending and smoothing tools, my work became that much easier."Much has been said about the road to success but I think the clearest answer is, that it simply takes desire, perseverance and a bit of talent. Simple, yes - always easy, no. The common quote that "It takes 10,000 hours to be good at something" is not far from being correct. Constantly looking at the world around you and visualizing how that special item was created, fuels the fire of imagination. Breaking pieces down to the most common denominator, as James Booth is fond of saying, opens up possibilities when considering new design ideas. My early hours and late nights, staring into the Aspire screen, is no different than someone going to night school while holding a "regular" job. There are long hours that hopefully will pay off in personal satisfaction for a job well done. But first, you must love what you do…if you can find that, as they say, you'll never work another day in your life."

"The novelty gift "PinArt" also helped me understand the 3D side of Aspire. The "PinArt" gift is made up of thousands of straight pins that, if you put an object under it, the pins would rise up, or lower, to mimic the 3D shape of the object. This connected with my understanding of the pixel aspect of Aspire. Making a mistake or wanting to change the look of a model in Aspire is far less costly than attempting to change the slight bend of a head in a wooden statue. Simply put, Aspire, with its "what you see is what you get" renderings, allows me the ability to try new approaches to design ideas without the worry of wasting material."

Michael continues by telling us about his latest business venture and the beginning of a new idea to teach sign design concepts to CNC users.

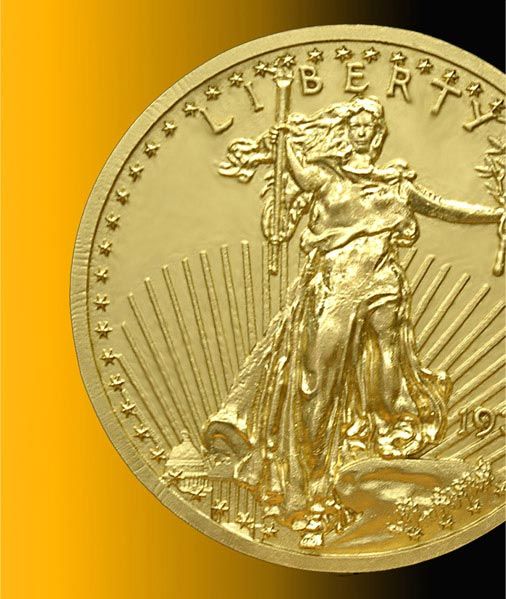

"Recently, a new venture has grown from my involvement with Vectric software in the designing and modelling of signs, official emblems and varied items for other companies. We make the file from the supplied image and they produce the finished product. Having developed a design and fabrication business (that only does custom work) we are no stranger to the wants and needs of the individual client. Products have been as varied as the seal for the DEA Caribbean Division, an Alaska State Trooper badge, several restaurant signs and recently, the modelling of famous US Coins for a numismatist."

"My future goal is to expand this part of the business, offering to other CNC fabricators, design and file creation services in the event that they are overloaded with their current workload or simply wanted a new and unique look for an up-coming project."

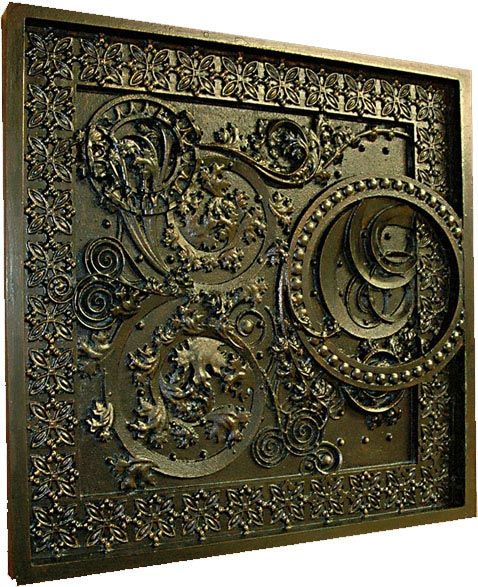

"A special project that we are currently working on related to design, in conjunction with Tony Wish, is the development of a school for sign makers. We have seen a great need for some type of organized design education in the field of sign making, so it is encouraging to hear so many people show support for this idea. As with any organization, there needs to be a logo, or some other recognisable marking. I chose the concept of a Victorian style carving to express the idea that attention to detail is most important in designing. Curls and swirls and the human form are used in many signs we see, but the lettering style is equally as important. This is just one small part of what we want to explore."

"So, the design for the school masthead grew out of the intention to show grace and elegance while stirring the memories of the quality of craftsmanship from long ago. We expect that Aspire and all of the other Vectric programs will play a significant part in the school's curriculum as a way for students to express their design ideas."

To finish, Michael lets us know what projects him and his team are currently working on.

"We are currently involved in the early stages of a project to replicate a series of highly decorative stained glass panels, fabricated in 1930 for Yale University. This project consists of cutting thin sheets of lead to form a pierced overlay for the stained glass windows. Then, by using a soldering iron, apply a texture that simulates wood bark. The CNC machine, with its ability to reproduce the tool paths for multiples of the same design makes this project less stressful when having to be exact with the pierced cut-outs. By using Aspire I am able to develop the required vectors and tool paths to match the exacting standards of the Consultant, Architect and Members of the Oversight Board for the University."

"Another project we are currently contracted to fulfil is the fabrication of the large wooden frame for a stained glass window that was severely damaged in a recent church fire. Again Aspire, with its 2 rail sweep option along with my CNC machine, will do most of the work."

"In the end, I got to be what I always wanted to be…………. Creative!"

We would like to thank Michael for sharing his experiences with CNC technology and Vectric software with us and look forward to following his continued progress on the Vectric forum /forum

You can follow Michael under the username 'Mezalick' and also via his websites below:

http://www.mezalick.com/MDS/Home.html

http://www.carveddetails.com/

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions