This months focus is all about spreading kindness at Christmas so let’s get you in the spirit of the season and see how one of our very own Vectric makers created an extra special project for his local charity. I bet most of you have already spoken to Simon Oakley because he’s one of our Support team offering our customers technical advice. Well Simon never shies away from a supercharged schedule and on his days off he’s always busy creating chips in his own wood shed for one project or another. Let’s find out what Simon gets up to in his spare time and how he helps his local community upcycling materials using Aspire.

Simon, tell us a bit about yourself and how you got into CNC.

I live a few miles down the road from Vectric on 1.5 acres of land with a huge greenhouse, big polytunnels and an aeroponic setup which sprays water and nutrients to help the crops I’m growing. We’ve tried livestock on the land too such as chickens, turkeys and ducks and the future plan is to have a small holding for me and my wife as she has a sewing and repairs business. We would like some mohair goats as the fleece is really soft and ideal for spinning wool. I’ve been an IT manager for 12 years but I’ve also had a wood shed for some years with various bits of machinery and tech. My route in was 3D printing, laser then CNC and I’ve got two 3D printers and added a laser cutter 18 months ago cutting bits and pieces, so I learned about how the software works on CNC then.. I joined Vectric 8 months ago and the same day I started, I went out and bought my first CNC! I used to do my own fun projects in the Vectric Labs but got so hooked that I felt the need to have a dedicated machine just for cutting my own projects.

Can you tell us which machine you have and how easy was it to set up as a novice?

This latest addition is an Ooznest WorkBee Z1 entry-level machine with a 1500 x 1500 mm bed size and is a self-build kit so perfect for me as I’m just getting started in CNC. Having IT ‘know-how’ does help you get a head start but it’s been trial and error setting up all the bits, so having my colleagues Charlie and Mark in the Support team as backup for advice and real-world guidance has really helped me. Luckily I’m quite handy anyway and I love a challenge. Me and the wife absolutely love learning new stuff and it gets a bit addictive so I’ve quickly picked up how to cut projects and some of the finishing techniques for signs like epoxy inlays.

Wow that’s a really impressive setup! How did you get involved in the local community and what was your first big project?

We have a local Facebook page [called “The Only Way is Wythall, Hollywood & Earlswood”] and a good friend who’s on the group lets me know about good causes so I get roped into lots of community stuff. During the first lockdown I was asked to make bunnies for a local kids Easter trail that people could buy, decorate and display in their homes or around the area. I bought a load of 6mm MDF and made some bunnies but it was so successful that my neighbor, Dave at the timber yard got more stock for me and we ended up making 900 of them! I cut them and glued them all up then they were sold to families who did a brilliant job of decorating them. We even had judges going around and the winners got prizes. Some well-known local venues got involved in the fun too like Wythall Transport Museum and Beckett’s Farm who had a number of bunnies for their Easter events. The one I remember most was a lady who turned her bunny into The March Hare and themed a whole display The Mad Hatter’s Tea Party and that was spectacular. The funds raised £3,000 from the bunny sale for local animal rescue charities Ray Dedicoat at Hollytrees Animal Rescue Trust at Wythall.

That’s really generous giving your spare time up for such a good cause. Tell us how the Acorns Children’s Hospice project came about.

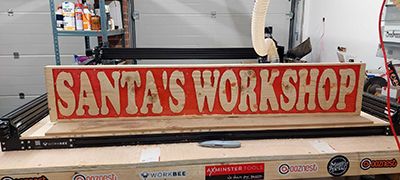

Acorns is a local charity and my neighbor is a nurse there providing palliative care for babies and children with life-limited or life-threatening conditions. They’ve been going 34 years and really make daily life magical for the kids but they always need of donations. They had a tired-looking Santa’s Grotto they wanted to look a little more loved for this year’s Christmas activities and my nurse friend said “We’re gonna do it but haven’t any budget; can anyone help”. Everyone rustled together and came up with second-hand fairy lights, baubles, trees, a throw for Santa’s chair and a backdrop to make into the fireplace, then I offered to create a sign to theme the front. I’d already done a Santa’s Workshop sign for my grandkids and they said “yes we want that please!”.

How did you go about sourcing materials and making your Santa sign?

It was basically all upcycled materials and believe it or not I managed to find some reclaimed 8ft scaffold board out of a skip. I cut the board in half to fit my work bed, planed it all up level and ran it through the CNC then added the lovely red epoxy pour coat to bring out the lettering. It was great to use our software for something outside work for a change and teaming that with the new CNC to test it out. I used Aspire to create the lettering and box around the frame but it would also work in VCarve or even Cut2D, then I pocket-machined it all out to a depth of 3mm and simply backfilled it with epoxy. I like the natural wood grain to show so I left the letters as wood to show a more rustic feel.

It must be really fun to see everyone enjoying themselves with things you’ve helped make.

It’s the only way to learn about CNC, getting in there and bothering and battering wood. I’m not artistic but more of an engineer so the light bulb moment for me was being able to draw something and actually make it into a real thing. It really clicked for me: that’s my idea, that’s my drawing, that’s what I make. And it’s the sense of community and giving something back. My in-laws were talking to friends who mentioned walking around some local woods and seeing cool new benches with lovely signs on. Of course my father-in-law chips in with “Oh Simon made those”. That was a project I made for an environmental group that I like to call the ‘Shirley Treehuggers’. I jest but they stopped 300 houses being built on woodland and our community donated 2 benches from Earlswood Nurseries to create a little seating area for walkers to enjoy the view and they and asked Simon to make the signs for them. To tell people the story. That’s when it really hits home that you’re making a mark, a permanent thing for people to enjoy for a long time”.

Hey, that’s a fantastic idea to create signage telling such an important environmental story for people to enjoy. I guess using sustainably sourced materials are important to you for the same reason. What do you use?

I use anything useful I can find in a skip such as MDF, pallet board and scaffold board. I love the environment and try to upcycle and reuse as much material as possible as it’s way better being repurposed than going into landfill. The price of materials has gone up with the energy crisis as people are burning more offcuts to keep warm, so there’s a bit of a shortage but there’s always something to be found in reclamation yards and of course free-cycling sites, not just skips!

Are there any future CNC project plans afoot in the Oakley household?

Mostly I make signs and community displays but I do have an interesting 3D guitar project I’ve started working on for a friend who’s a guitar luthier. I’m cutting blanks for him to work with using pallets which I ‘stole’ and used a pallet pry bar to take apart. I planed them all up so they looked nice and glued them together and you get nice big wooden sheets for nothing! When Tim Sway came over from the US to visit Vectric, I managed to get an hour with him to talk about his upcycling and recycling to see if he did anything different to me in the way he creates the files Aspire and how he machines the guitars. It was reassuring to find out he does pretty much the same... We both spend a lot of time diving in skips!

Well thank you Simon for taking time to share your CNC journey. Check out the project gallery showing the variety of work Simon has created in such a short space of time since learning how to get into CNC.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions