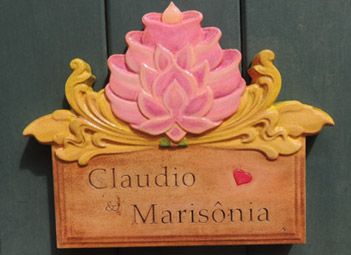

This month we have been talking to a VCarve Pro user, Claudio Pontes who is located in the city of Mogi Guaçu, in the northeast of the State of São Paulo.

Claudio currently works full-time as a Forest Engineer, cultivating Eucalyptus and Pine trees but he has plans after he retires to move into working full time on creating decorative products for home decor and other wooden products. To prepare for his future business he works in his spare time with his CNC Router and VCarve Pro to build up a portfolio and develop his design and manufacturing skills. Claudio’s CNC is a high quality “home-built” CNC router with a working area of 1600mm x 2200mm (63” x 87”). Claudio’s interest in CNC came from exposure to a different kind of computer controlled device from a previous job, we asked him to tell us about how this developed into building his own CNC.

By the end of the 1980's I was working for HP in Brazil performing maintenance on plotter machines. At that time the colour printers we know today didn’t exist yet, there were only dot matrix printers with tape similar to the old typewriters. The plotter machines were driven by a "stepper- motor" along the X and the Y axis and I was delighted with the precision and speed of the drawings, which used a carousel of 7 special pens (1- black, 2 red; 3 blue etc). The exchange of the pens also enchanted me. Since that time I was truly in love with this method of movement in XY. Recently I decided to return to this “old flame” by building a CNC router machine.

Claudio’s venture into his hobby happened step-by-step, before having the machine he decided to invest in the software he had chosen (VCarve Pro) and learn this during the year it took to build his CNC router...

I bought VCarve Pro a little over a year ago and since then I have been learning how to program with it. The ability to preview the result is a very strong point of the software. This has allowed me to create numerous projects and see exactly how they will turn out even though I was unable to cut them until my CNC was complete. During this period I have been building a CNC router with the assistance of an Electromechanical Technician. The machine was ready by the end of March 2015 and since then I have been putting into practice the projects that I have created during the year.

Other than his love of the mechanism of the CNC we wanted to know what Claudio planned to make with his newly finished equipment. We were also interested in how he settled on choosing VCarve Pro even before having the machine finished.

Primarily, due to the influence of my job, I want to create things that are made with wood. With this in mind, I started researching the different applications for wood in artistic design (like signs, trophies, etc). After discovering that a CNC router works as well with other types of materials, such as acrylics and PVC I have been dedicating time to find more about these as well. With regard to the selection of software to operate the machine I researched a lot until I found Vectric which had the best solution for my needs. The excellent video tutorials and the affordable price of the software were the main reasons for choosing VCarve Pro. So far I have watched approximately 70% of the video tutorials and am very satisfied with the results.

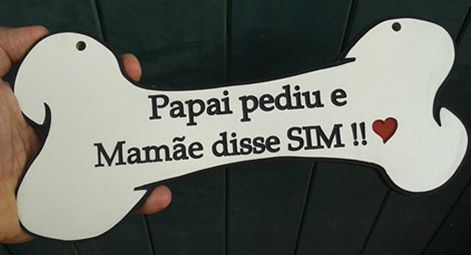

After investing his time in research, learning and creating Claudio is now gaining ground in taking his CNC skills further by producing signs for births, weddings and other celebrations in MDF. Although he programs VCarve Pro and operates the CNC router it’s his wife Marisônia Pontes, with an aptitude for fine arts, who gives the final touch to the parts by applying the stain or paint. Literally creating a perfect marriage of skills!

Although Claudio prefers creating signs he is inspired by the diversity of ideas that can be made into reality and the level of accuracy that can be achieved with a CNC. He enjoys walking down the streets and searching for ideas on Pinterest to feed his creativity.

For the moment, he considers himself being in the “embryonic” phase, researching the market needs and testing the abilities of the machine. Claudio uses everything he works on as part of the learning and discovery process, finding out the maximum productivitywith a specific type of tool, material, speeds etc. along with other challenges to do with work-holding etc. As any new CNC user knows each of these lessons helps you get closer to producing perfect parts!

Certainly looking at the images of Claudio's parts he's made so far he appears to be learning fast how to make and finish some nice looking projects. To conclude our brief chat we asked Claudio what he intends to do with his CNC going forward?

My plan is when I retire in 8 years to dedicate myself full- time to the business, hopefully with the involvement of my family. In the meantime I intend to work on designs and ideas and get a full understanding of my CNC so I will have the full technical knowledge and a good vision of the products that will be well received by the market. There are many products that I still want to try such as kinetic-art, lithophanes, luminaria, the use of the 4th axis etc.

We would like to thanks Claudio for taking the time to talk to us about his use of VCarve Pro with his new CNC and sharing some of his early projects, we look forward to seeing much more of his work in future on the forum (Claudio’s user name is “clpontes”).

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

GB115123072

Privacy Policy |

Terms and Conditions