After retiring, Joz Britz decided to set up and run a woodworking shop from his home in South Africa. His focus was to produce high-end, corporate gifts in solid wood. His early work was all crafted by hand, but during 2006 he started looking for methods that would help him become more productive and discovered CNC technology;

“I visited a friend who had just bought a CNC machine and I immediately saw the potential for my small workshop. I did some research on the internet and came across a huge amount of information and also a large number of machines in various price ranges.”

After choosing a suitable CNC machine within his budget, his attention turned to the available CNC software. As it turned out, the manufacturer of the CNC machine also advertised which software was compatible with their machine, which helped Joz compare the options.

“This was the first time I saw the name Vectric. After going onto the Vectric website and reading about VCarve Pro, Cut 3D and Photo VCarve. I downloaded the trial versions of all three products and was amazed by the ease of use and how user friendly all three products were. I made a decision to buy all three products” .

Joz started his learning with small projects using VCarve Pro, designing some simple clocks with V-Carving which were received very well by his clients, this lead him to pursue more advanced designs.

Looking to design more complex pieces, Joz decided to upgrade to Aspire when it was first released as it would help him to visualise the assembled design elements within a 3D view before manufacture.

One of Joz’s first projects was to design and cut a Grand Geneva wall clock with a scroll saw pattern cut,

“I saw a photo of a scroll saw clock in a magazine and was convinced that it would be possible to cut a scroll saw pattern with Aspire on my CNC machine”.

This is a description of how Joz used Aspire to prepare the design and toolpaths for cutting the Grand Geneva Wall Clock on his CNC machine.

Design Process

1. Importing and vectorising the pattern

Joz first scanned in the Scroll Saw plan/pattern that he had bought and imported the resulting .JPEG files into Aspire. To ensure that the vectorised images would all be to the same scale, Joz created a working area in Aspire the same size as the original plan/pattern. Depending on the type of clock, the plan/pattern can consist of up to 10 x A-1 size pages (900mm x 600mm).

Aspire then created vectors based upon the pattern artwork. After using the special ‘Node editing’ tools in Aspire to tidy up the vectors and remove the unwanted elements, the vectors were soon able to be used to generate the design for the individual parts of the clock.

2. Editing the design for the chosen CNC toolbit

As Joz only has a small selection of machine tool bits to select from, he runs a quick toolpath preview in the software, using the “Solid” option to help visualize the path and clearance of the toolpath with the end mill tool he has available. Once he has done this, Joz is then able to optimize the design using Aspire's node editing tools to ensure a nice tight finish to the cut.

3. Grouping the parts for wood selection

After all pages have been vectorised and corrected, Joz then decides on the “color scheme”, deciding on which types of wood are going to be used for each part to give the best effect.

To keep it simple and also to keep files as small as possible, Joz grouped the individual parts with the same thickness together in separate files. For example; Grand Geneva-3mm file, Grand Geneva-6mm file and Grand Geneva-12mm file.

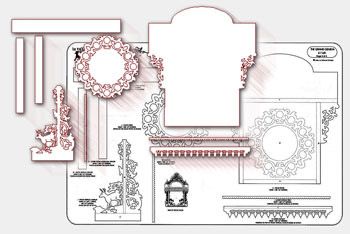

4. Creating the Nested Toolpaths

After creating the different files, Joz then brought the 3 groups of design elements together into one file, but using the layer functionality in Aspire he was able to organize and manage the 3 groups in one place. After using the True shape nesting capabilities to optimize the material usage for each group, Joz was able to create all the toolpaths for each layer

5. Using the 3D preview and Assembled View to confirm design before manchining

Joz is a big fan of the 3D assembly capability in Aspire;

“A huge advantage of Aspire is that one can virtually 'assemble' the clock before the time to get an idea of how it will look.”

“Aspire lets me group each entity with all it's vectors and allows me to “assemble” them using the 2D and 3D views and adjust the alignment of the parts.”

Joz was then able to set the material properties of each of the clock parts to preview a realistic impression of how the finished, assembled clock might look.

After this, Joz then machined out the various nested parts using a simple profile toolpath.

“It is my belief that after working with the Vectric software the user is only limited by his/her own imagination. For the rest - Vectric software is the solution!!!”

Joz Britz

Bronkhorstspruit

South Africa

Few other pieces of Joz's Work

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions