Shannon Walls bought his first CNC router from China around 2.5 years ago. After initially making do with the supplied CNC software that came with his machine, he soon became very frustrated with its limitations and many bugs, leading him to investigate other software options, as he describes;

“I was looking on the forums and saw that a lot of the other sign makers were using VCarve Pro. I tested the trial version and I was suitably impressed with the ease of use and also its great features. Eventually I purchased VCarve Pro and Cut3D along with PhotoVCarve and although I haven't used PhotoVCarve much yet , VCarve Pro gets used just about every day.”

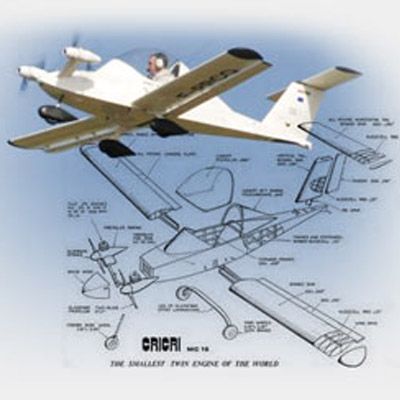

Shannon runs a successful, custom CNC routing service by day, but in his spare time he uses the machine to tackle various personal projects. In fact, soon after learning the CNC basics Shannon decided to take on a very ambitious project; to machine and build a form of light aircraft called a CriCri. Shannon agreed to share his reasons for taking on the challenge and his experiences in using Vectric software.

“The story behind my decision to build a CriCri goes back to a Classic fighters airshow in Omaka in 1995. It was there that I first saw the CriCri that Nev Hay has built. I was fascinated by the tiny aircraft. In fact it was very close to the plane I had dreamed about making when I was 12 years old.”

However, Shannon also explains that after he heard that the plane he saw took 2000 hours to build he was instantly put off, that is until he later discovered CNC machining and VCarve Pro.

More than ten years later and owning a large CNC machine, Shannon stumbled across the plans of the CriCri on the internet for download.

“Once looking over them I realised that it would be the perfect aircraft as a CNC project. I purchased a licensed set of plans from someone in Australia who was selling their set and got to work redrawing all the parts in CAD ready to CNC cut.”

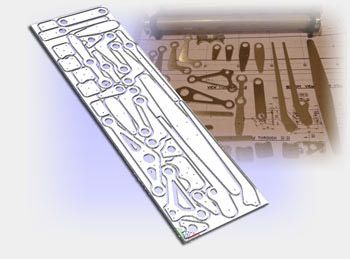

Shannon first drew out the parts in a CAD program that he had previous experience with and then went about importing the many parts into VCarve Pro for nesting into the sheet metal, as you can see from the example to the right.

Shannon imported and cut over 1000 parts in VCarve Pro for the project.

An example of one of the parts be seen below – the Pedal tray.

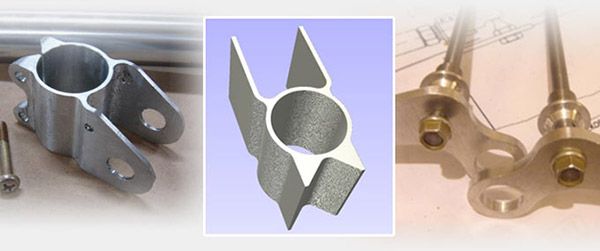

Some of the parts such as the engine mounts and elevator hinges had to be cut out of 32mm thick 2024T351 billet. These required a fair amount of material removal and I used the area clearance feature to remove most of it and then a profile pass to give a good finish.

A lot of the parts are hand finished by de-burring and sanding for a matt finish. Shannon extensively used the nesting and 3D toolpath preview features in VCarve Pro to be confident the finished result would match his requirements.

As Shannon is building this aircraft in his spare time the aircraft is still in production. Below is the aircraft as it stands today (Nov 23rd).

To follow this amazing project please follow the build story in thisforum thread.

A great thanks to Shannon in sharing his story and Good Luck with the project!

"I would like to thank Vectric for making such a powerful piece of software but still enjoyable and easy to use. Vcarve Pro makes my CNC projects all that much easier."

Shannon

http://www.remain.co.nz/

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions