For this month's case study we got in touch with Vectric Aspire user Daniel Flathers, owner of 'Daniel Cabinets', after seeing a number of impressive projects he created on the Vectric forum.

In this article, we learn more about Dan's unorthodox entry into the world of CNC, as well as further information about how he created three projects we highlighted from his impressive portfolio. We also share links to some of Dan's other creations at the end of the case study.

We start with Dan telling us about his experience prior to CNC…

Before CNC I was a heat and air conditioning contractor, but woodworking was a hobby that I always really enjoyed.

After a major shoulder injury in early 1995 I decided that it was time to make a career change so I started my own business 'Daniel Cabinets'.

In 1998 I was approached by Trailwagons/Chinook (an RV and Truck/ Van conversion manufacturer) to head up their new product development. I sub-contracted with them until they closed their doors in 2005. But what a great experience that was. They paid me to learn and design new products. The exposure I received to new product development was priceless.

As it stands, I am self-taught in my field and always looking for ways to stay ahead of the curve. I always like to learn new things… this is where CNC comes in.

In 2007 I started looking for something to help take my business to the next level. So I decided to find an affordable CNC machine and ShopBot fit the bill. The fun thing about all this is that I knew nothing about operating CNC equipment and had little knowledge on the use of computers! It was interesting when my new equipment showed up in a big crate and a manual on how to assemble the machine. It was a bit overwhelming, but as I said - jumping in with both feet is what made it fun.

After setting the ShopBot up I decided to look for some user friendly software. Whilst looking around I decided that Vectric offered the greatest ease of use, so I bit the bullet and purchased Aspire.

All in all it took me about a year of trial and error before I felt completely comfortable with what I was doing with my CNC. The biggest hurdle was realizing that all mistakes were my fault. If you program it, that's what it does. It was quite the learning curve.

Dan goes on to tell us more about three of the projects he has produced that we chose from his wide collection of work. He tells us how he came to create the pieces, as well as the materials and finishing products he used for each one.

Work Station

"This project is for my office/ showroom that I am creating for my potential clients. I want to show them how I can offer different options on the work I do for them.

I was trying to create a functional work station that also had a fun theme with an antique look. I am also trying to demonstrate how you can have multiple wood species and colors in the same room.

In terms of material, the cabinetry is manufactured with brown Birdseye Maple. The countertop is thermo treated ash with black stain and finished with polyurethane. The window trim and base board is Western Curly Maple with a clear coat lacquer and the corner blocks are also black stained brown Birdseye Maple."

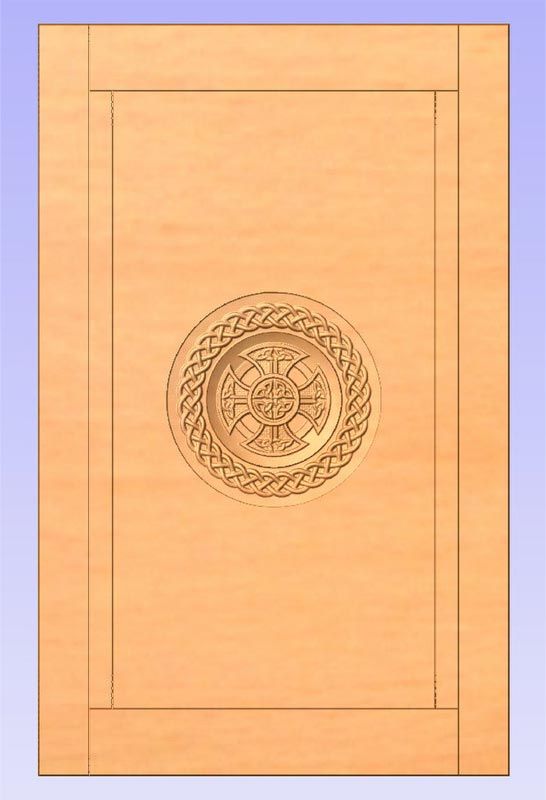

Sideboard

"This is another piece that I created for myself.

I really wanted to play with Vectric's Aspire software to see what could be done.

On the wall above this sideboard I also have a sword display, so I wanted give the piece a Celtic theme. I call it "building antiques".

The material used is brown Birdseye Maple. I used black stain which really highlights the carvings. Then a dull rubbed lacquer finish. I also like to leave a lot of the tooling marks on the cabinetry, when stained it gives it an aged look."

Truck Conversion

This project is for an existing client, it was particularly good to work on as I have a history in truck conversions. The client's father in law was a tail gunner on a B-17 bomber in WWII, so he wanted to build this truck as a tribute. He dropped the truck off to me and said have fun customizing the inside. This is what I came up with for him.

The wood is Curly Maple w/a clear coat. The glove box face has a B-17 bomber carved in the face then resin poured. The steering wheel, dash and center console were milled using CNC, it really added a nice flare. All of the VCarve and 3D carving were resin poured to maintain clean lines. The first time he showed the truck he was voted best in show. It really was a great project.

Overall, I am really enjoying CNC with the use of the Aspire software. It has taken my business to the next level, just as I wanted and I now have other cabinet shops referring clients to me because they are unable to meet their needs. One of the phrases I use to describe my unique skills is "I specialize in specializing", this has been enhanced significantly by using the CNC and Vectric software.

For the future I am already busy working on a custom kitchen with a Bali theme and also building a couple of different fireplace mantles.

We would like to thank Daniel for taking the time out of his busy schedule to talk to us about his projects and we look forward to seeing what he comes up with next.

If you would like to see more of Dan's work, then click on a category below to see that relevant gallery over on the Daniel Cabinets web site (www.danielcabinets.net). You can also find Daniel Cabinets on Facebook, and follow Daniel's posts on the Vectric forum by looking out for user 'danielbf'.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions