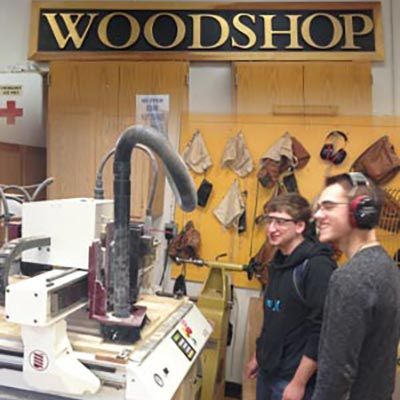

As the Vectric logo indicates, "We're passionate about CNC" so it's always great to see the technology and software being introduced to the next generation of users. Thomas Casey, a technology teacher at South Colonie Central High School based in Albany, New York, contacted us last year to demonstrate how his students have incorporated CNC into their technology curriculum. He shared images of some of the projects his students have created using their in-house CNC and Vectric software. Following Casey's initial contact, we were eager to find out more about how the school has utilized the technology.

We begin by learning more about Thomas himself, including his experiences prior to becoming a teacher and then how his focus switched to a career in education. He briefly tells us about what he teaches the students throughout the year, as well as how he deals with the overwhelming interest that the in-house CNC has generated!

We conclude by looking at the work of three of Thomas' students. Nicole Daley, Connor Hickey and Sarah Mooney tell us more about the courses they have taken to enhance their woodworking skills. They also showcase what they have created using traditional woodworking methods, as well as the CNC and Vectric software.

"I have been in my current position as a Technology Teacher for the last 13 years. During this time I have taught a host of classes including Construction, Wood Technology (intro to woodworking), Advanced Woodworking, Design and Drawing for Production (CAD), Computer Graphics (intro to Photoshop and Illustrator), and Cisco Systems sponsored programs.

I have always been interested in woodworking. Most of my decisions and directions I have taken originated from my experiences growing up. I was a kid, who like others around me was a good learner by watching how things got put together and working with my hands. When I first took Technology classes at junior-high level, I was hooked. While in high school, I decided to join the Navy and Enlisted in the Seabee program as a builder (basically a carpenter for the Navy). I had the pleasure of visiting many places during my five year enlistment and was most happy being attached to Naval Mobile Construction Battalion 7 before I was Honorably Discharged.

After the Navy, I enrolled in the technology education program at the State University of New York at Oswego. Where I had opportunity to reinforce my skills in woodworking and other applied sciences.

As I started to teach at Colonie, the administration wanted to phase out woodshop classes. I think this may have been because in education there was a shift from traditional technical courses to more of a science and math emphasis. After many discussions with administration, our department convinced them that we could excite kids about those types of fields by including CAD and CNC practices in the woodshop. I believe wood is a great material to start processing because of its forgiveness and cost. They got the message and bought us a Universal Laser and then the following year an AXYZ Millennium router.

We were very excited with all of this and the students started to sign up in droves. There were some limitations to what we could do because of the software that was shipped with the machine so we explored other options.

I downloaded the trial of VCarve Pro and from that moment on we have never looked back! The things we have been able to do with VCarve Pro and Aspire have been amazing. Well I guess the pictures say it all.

We currently have 8 Woodshop classes each day and service over 200 students in the woodshop each year. We have had to turn kids away from taking the woodworking classes since our investment and we believe this trend will continue. When students ask if they can do something or if it is possible, I remind them they are only stopped by their own imagination. I truly believe that! We have run our machine late into the evenings with students to produce many amazing things.

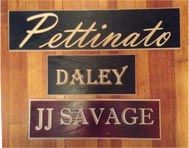

The first item I get students to work on using VCarve Pro is the simple family sign. It is very helpful to have the preview option for them to see what it will look like, allowing them to change on the fly before the final code is generated. During this process we introduce all the concepts (lift bottom, origins, tabs, etc) for the CNC and safe feeds and speeds. Then the imaginations run wild. We finish the year with the round table and they design the table legs and the tops.

It is also important to add that this environment has helped students believe that they are able to take our more advance track class in the engineering field."

To help see things from a student's point of view, Thomas worked with three of his pupils that are directly involved with the school's CNC equipment. Each of them kindly took the time to write a summary of the courses they have worked on and what they have created utilizing the simple yet powerful features available in VCarve Pro. We list the students in alphabetical order starting with Connor Hickley, then we move onto Nicole Daley, and Sarah Mooney…

"The courses that I have taken in the technology department include, CAD, CIM, Wood Tech, Advanced Woods and Digital Electronics."

The projects that I have made with the CNC router include a Cutting Board and Nantucket Bench.

VCarve Pro allowed me to get a little more complex with my design than if I were to have hand-carved it. I plan on using the CNC router before I graduate to make a 3D engraving of a Celtic knot, a cell phone case, and a speaker housing. My future goals are to use the software to speed up the conversion of virtual 3D models into actual physical models. I plan on using the program in the future as it makes wood working so much easier." Connor Hickey

"I have taken a few technology classes which include basic wood technology, advanced wood technology, auto specification, and passenger car chassis. I have completed many projects in the wood shop and I have made several different types of cutting boards, a jewelry box, a self-folding stool, a pencil box, a Nantucket bench, round table, a baseball bat, and numerous name signs.

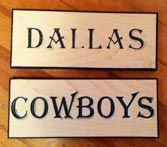

For the table top and the name signs I used the CNC. A hurdle I have faced was with the design as I have never used a computer program like VCarve Pro before. However, the software helped me in the layout process because it was very easy to use. Before I graduate this year I would like to make the Marine Corps seal and the Dallas Cowboy logo." Nicole Daley

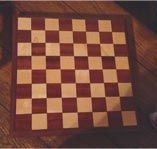

"Whilst I have attended Colonie Central High School I've completed both the standard wood tech class and the advanced wood tech class. Within those two courses I've made a checker board, shelf, folding chair, round table, a bench, cutting board, name plate, and a pencil case. When working on these projects the obstacles I often faced had to do with my impatience and my lack of ability to precisely measure with a ruler.

The VCarve Pro software I have been using in wood tech helped me be creative and unique and also be true to myself. Before I graduate I'd like to make a sound wave and also a phone case.

One of my favorite projects that I created would be my round table. Like every other project we started by sketching and finalizing measurements before we made them a little bit more permanent. I remember that designing the legs to my table was the hardest part of my project but it was worth it. My legs looked like no one else's in the class, they had ridges and holes down the center. The top of my table was created by using the CNC router. My design was made up of three long Celtic knots. Throughout the process of making my table I used the table saw multiple times as well as the miter saw. Also I was constantly sanding down new parts of my project. Attaching all the pieces together was very difficult, the legs to my table we very brittle which made them hard to glue and place so they didn't shift while they were drying. Overall I loved this project but it had many complications in the end, the most noticeable one must have been the uneven sanding on the top of my table. I had a very hard time controlling the power sander. After I finished this project though I actually felt like I was good at woodworking.

Another project I really enjoyed was the pencil case project. Now this project wasn't only for fun it also counted as our final exam! My end result was the best part of the whole project, it made overcoming all my obstacles worth it. I struggled with angle cuts to make the sides flush. Other than that the only other main issue I had was my project shifting while it was drying! The CNC router made this project look so good. My design was a peacock feather and I remember how fine the router bit was because of all the detail. I used the miter and table saw for this project as to a ton of sandpaper and many visits to the belt sander because I needed my project smooth. Overall this project helped me with measuring and gluing my projects right." Sarah Mooney

We would like to thank Thomas for taking the time out of his busy schedule to talk with us. We look forward to catching up with him in the future to see what other interesting projects he may introduce into the schools curriculum that utilize the power of CNC.

If you would like to learn more about South Colonie Central High School, please Click Here.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions