Kelly Watkins, the supervisor over ‘Aircraft Metals Technology’ division on a US Air Force Base in Louisiana, contacted us to let us know of a couple interesting early projects, following a recent purchase of VCarve Pro. 'Metals Technology' is essentially the Air base’s Machine/Welding Shop. They currently have several CNC and Manual pieces of equipment including a Fadal VMC.

Project 1 – Presentation Shield with VCarve Detail

Kelly’s team was tasked by the 8th Air Force to assist them with a special project. Since WW11 the 8th Air Force have had a British RAF position with them who fly with them on the B52 aircraft and live in historic housing on base. After almost 60 years the RAF position is moving to what is called the Global Strike Command.

“The 8th Air Force asked us to build a shield to present to the RAF for appreciation of their service.”

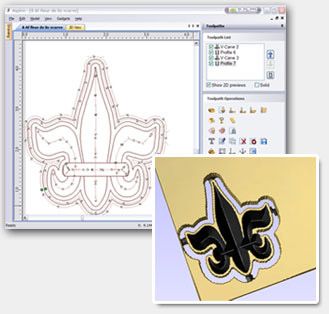

Kelly had some doubts over successfully achieving certain areas of the shield design. The majority of the shield was planned to be machined using existing conc software and manufacturing techniques, however there was a particular design element to the shield that Kelly needed to machine with a V-Carved effect: A 3D Fleur De Lis that simply could not be machined with the current software program;

“We currently use another general CNC software product on our Fadal VMC and although it is very good at general CNC it is certainly limited in the artistic area unless you have the 3D design created elsewhere….

…So in came VCarve Pro to the rescue! We received a copy of VCarve Pro with our recently purchased Dynacnc machine, however I had limited chance to try out the software on it up to this point. I had been itching to try in on our Fadal so this was my opportunity to try it out on some serious material.”

Machining the Fleur De Lis:

Kelly used a VCarving toolpath and a 90 degree spot drill/chamfer mill to engrave the detail on a fleur De Lis which was to be machined out of .500 solid 7075 T7 aluminum.

“It turned out pretty cool. We were really pleased how well VCarve Pro worked on our Fadal CNC.”

The detail achieved on the shield impressed the 8th Air Force so much that Major General Carpenter (2-Star) came down to the machine shop personally to thank everyone involved.

Project 2 - Leaving Gift

Encouraged by the success of the first project Kelly saw the potential VCarve Pro offered his team and quickly chose the next project that would employ VCarve Pro exclusively for all parts of the design creation and cnc manufacture.

“After being impressed by how well VCarve Pro worked when creating toolpaths for Aluminum machining, I just had to try something else…

As one of my troops was leaving and heading to Korea, we decided to create him a VCarved plaque”

The plaque would include a 3D VCarved version of the Air Force Logo and be machined out of 1/2" thick 7075 T6 Aluminum plate.

Before machining the full plaque Kelly wanted to test out his new VCarve Pro skills by machining the logo in isolation. Kelly did have some concerns over holding the piece in place whilst machining removing it from the waste material after, however Kelly explains;

“I used the awesome tab feature in VCarve Pro. Previously, machining parts like this we would leave .010" - .015" on the bottom and knock the part out using a hammer. The tabs are great!”

“We machined it with a 1" diameter 90 degree spotdrill/chamfer mill and profile machined it using a 1/8" two flute ‘high speed steel’ end mill.”

Spurred on by the successful machining of the logo Kelly moved on to the machining of the whole plaque.

“With the plaque I was definitely trying some new techniques. For the first time wanted to try and use a 1/4" dia X .005 X 60 degree point engraving tool to V Carve some smaller text. On the design (screen shot) you will notice two round pockets. Those were to hold two MXS (Maintenance Squadron) coins. One for each unit that the leaving trooper was assigned to on our base”

After the plaque was machined Kelly added some blue paint to the AF logo and some red to his name. The top was then regrained using 120 grit sandpaper and the two MXS Squadron Coins were fitted into the machined pockets.

“This project was done completely with VCarve Pro. It gave me a chance to practice with numerous features in VCarve and I probably did some unusual tool path strategies in alum but it worked pretty well I think!”

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions