Dean Lutes, founder of Wonders of Wood, has been a traditional woodworker for the past 21 years. After leaving his career in heavy construction he started his own business and is currently working out of a self-built cabinet shop near his home in Tennessee. Over time he has managed to secure a large number of store install contracts for companies such as Laura Ashley, Ann Taylor, Williams Sonoma, Disney, Pottery Barn and around 200 Blockbuster Video stores across the US and Canada.

In this month's case study Dean tells us about his decision to start using CNC technology and how he used this to create the Church Booth you can see in the image to the right.

"The Church Booth project we did for All Saints Chapel in Sewanee pushed us into the 21st Century as far as technology is concerned. This job required identical and repetitive carved panels for the booth which would have taken a VERY long to time to create if someone was to carve them by hand. Having done some hand carving, I knew that there were easier and more accurate ways to create this project using CNC technology. I have been watching CNC ever since I became self employed in 1990, but never really wanted to use it because I wanted to stay hands-on. Over time though I have lost interest in carving and never really learnt to hand carve efficiently, so after considering a CNC for 21 years I finally convinced myself that the technology could carve better than I could so I decided to invest in a 48 X 96 Laguna Swift.

When choosing a CNC machine the price was important, but it was not the deciding factor. I chose the Laguna because of the solid steel welded frame that I can retrofit with a vacuum table when I'm ready, I also chose Laguna because of their support team and training.

To help design my projects I use Vectric software along with Cabinet Vision. I first discovered Vectric software when I attended a Cabinet Vision User Conference and they demonstrated Aspire, showing how easy it was to design all kinds of parts that will easily import into their software. I could see how user friendly it was straight away; it was nothing like all the other CAD programs I had been looking at. I loved it there and then and decided to purchase the software in a package deal with the machine.

As I had never used CNC before I always questioned whether this technology was right for me, but looking at the finished project proves that it definitely is. Vectric has opened up a whole new world for my company 'Wonders of Wood'. We are already getting requests for carving headboards for beds and bed posts and we are replicating ginger bread trim for some of the historical homes in the gated communities. I have also been asked by one sign company to do carvings for their signs - all these contracts came from word of mouth advertising. We can also now do carved panels in our cabinet doors without having to outsource it."

Dean goes on to tell us how his company was chosen for the custom church booth contract and details the steps he took to finish the piece...

"On this particular job at All Saints in Sewanee, I was told that there was a donation made in the amount of my bid and that the donor specified that they wanted 'Wonders of Wood' to do the job. To this day the donor remains a secret and that is OK with me, I'm just happy to know that someone has that much confidence in the ability of 'Wonders of Wood' to do a project like this. We don't cut corners; we use the best materials we can find and I try to buy the best tools (like Aspire) so we can produce the best products. We also go to training classes to learn the best work methods so that we can give our customers pretty much whatever they want.

When we won the booth contract we were still waiting for the Laguna CNC machine along with Aspire to arrive. Whilst patiently waiting we decided to not waste time and start preparing what we could by overlaying the booths existing 2X4 and ¼" plywood walls with ¾" B-2 domestic Birch Plywood (as seen to in the image, left) to create the different levels of finished surfaces. We then measured the booth again and designed the panel sizes in Cabinet Vision for a perfect fit. Whilst we were doing this I also took rubbings, traces, sketches, photos and many measurements of the area of the Chapel that we were told to replicate for future reference.

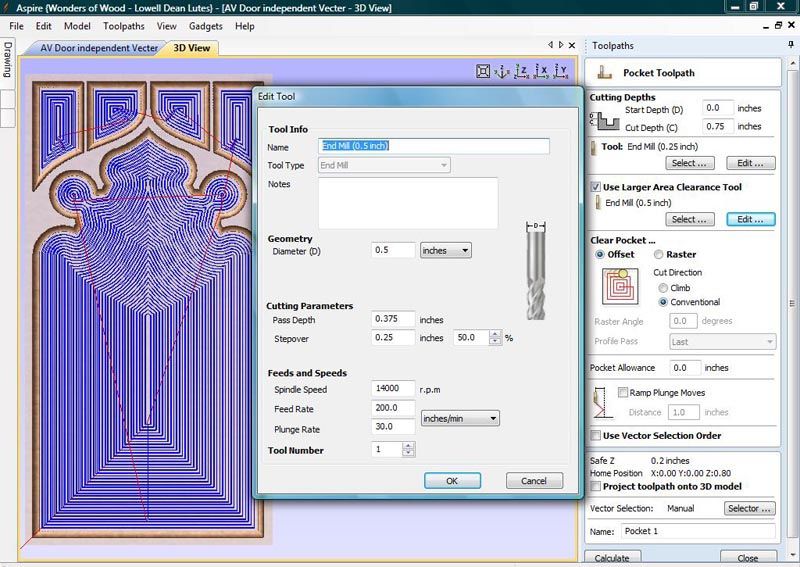

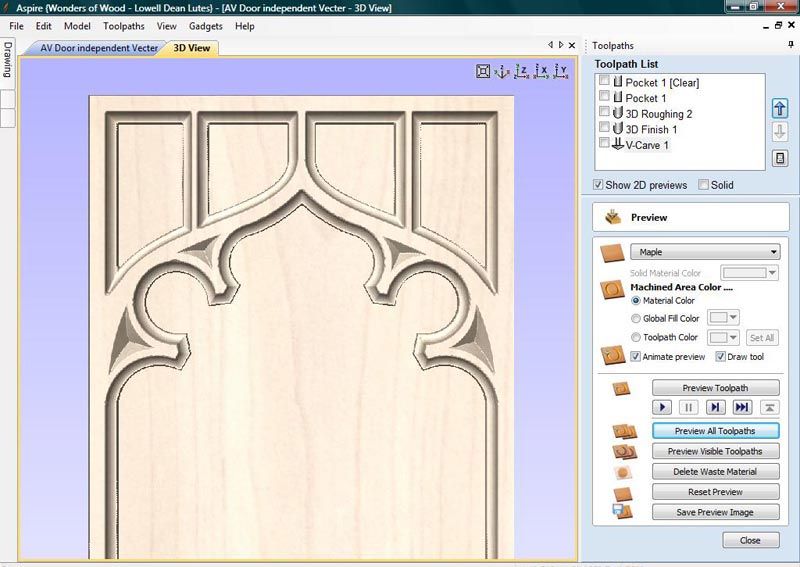

Once the CNC and software arrived we set it all up straight away, built a holding jig and went to work sizing the panels. At this time I still didn't know how to model or machine anything, so I sent 'Router Bob' from Laguna a photo of the panel design that you can see to the right, including the final dimensions to see if he could help with the project. Bob was very helpful and soon arrived to demonstrate all the modelling & toolpath processes in Aspire.

Despite Bob's generous efforts to help, there wasn't enough time for me to learn how to design this particular panel in Aspire. Because of this Router Bob very kindly created the design files for me using another program and then we imported the files into Aspire to generate all the toolpaths.

As I mentioned earlier, I try to learn as much as I can to help give our customers whatever they want, so whilst attending IWF 2012 in Atlanta, I met James Booth from Vectric and asked him if it was possible to create the door panel using Aspire. Immediately he demonstrated how easy it was to create this design and went on to teach me every step. So if I ever need to create anything like this again then I can confidently produce all the vectors and toolpaths for this design in Aspire by myself.

The toolpath features in Aspire are very user friendly; you can see the main toolpath settings I used in the images below. The ability to cut the coved area of this entire project is the main reason I chose CNC over hand carving. The 2 rail sweep in Aspire is a life saver for me and after attending the 2012 Vectric User Group Meeting I got to see the true potential of what you are able to create with the sweep tools. I really can't wait to start designing and machining some new designs.

The last thing to do now was to match the finish for the panels. I must say at this time that I believe I have one of the best finishers in the industry, Brandon Nunley. He can walk onto a job, look at it, go back to the shop and hit it right on 99 times out of a 100. I am so thankful to have him on my team. For the finish we used Mohawk finishing products and after a good sanding job we started with Van Dyke Brown Glaze to help fill the pores of the Oak and help get an even color. Once this was done we applied 1 coat of Sanding Sealer and 2 coats of Pre-catalyzed Lacquer. The install went very smoothly and everyone though it turned out wonderfully.With the design, toolpathing and machining now complete, we ended up with some amazing panels. These panels are not glue ups; each one is cut from wide solid Oak Board and measures 1 1/2" thick by 10 & 1/8".

Upon finishing this project I would also like to share how extremely happy I am with Vectric's support team. This was my first CNC project and it was great to know that Vectric & Laguna were with me all the way. I found using the CNC and Vectric software exciting, challenging and very rewarding."

We asked Dean whether he created anything else after the fantastic booth project using his new found knowledge of CNC technology...

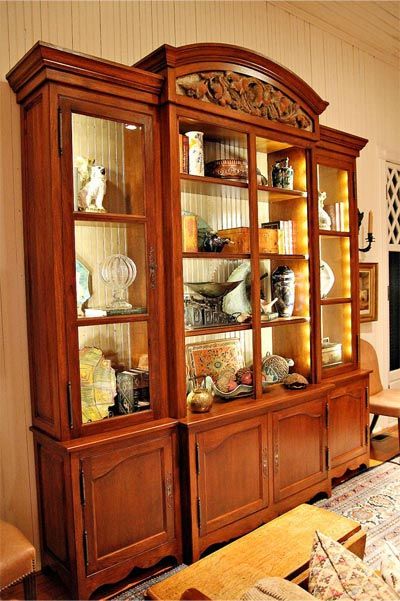

"After the booth project we did win another contract in one of the gated communities to produce the 9ft tall by 9ft wide Hutch that you can see in the image to the right. It's made of Butternut, or as some say around here, "White Walnut". We did use the CNC on this piece, but not as much as we did for the booth. We used it for the scroll work on the skirt boards at the base. The concrete scroll piece on top came out of an old Building in New Orleans, it was a window header that measures about 6 inches thick and weighs about 100 pounds! The finish on the bead board backs inside the cabinet has a 7 step finish...

This piece was very interesting to build as it had to be installed in 8 pieces, but it was worth it as everyone was very pleased with the final piece.

The latest contract I am currently working on is an outdoor architectural trim for a Historical Restoration of old homes in the area, at the same time I am also learning a lot more about sign design and carving which will be invaluable when approaching future work."

We would like to thank Dean for taking the time to talk with us about his project and for sharing images of his work. We look forward to seeing more projects from Dean's company 'Wonders of Wood' in the future.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions