Chris Welch is a hobbyist CNC user from Victoria, Canada and has been using Vectric's VCarve Pro & Cut3D software for the past 2 years. He is an active user on the Vectric Forum and one of this recent posts, a novelty Specialty Bolts sign received a lot of interest and compliments.

Following his forum post we contacted Chris to find out how he got involved with CNC and to learn more about this project. Like a number of our customers it turned out that running a CNC is not Chris' day job, however it was an experience at work that led him into his fascination with this technology. We'll let Chris pick up the story from here...

"I'm currently a Marine Engineer in the Canadian Military where we get a small introduction to the machining trade. Back in 2004 I was able to take a "Machine Specialist" course where I was first exposed to general machining, including CNC."

"It wasn't until I visited a local auction house that I had an opportunity for machining things to become a hobby. Whilst there I found a 'South Bend 10k' lathe, this had come from a high school who had updated their equipment. It was in great shape with minimal wear and tear, so I bought it and started to rebuild the lathe, but life soon got ahead of me which meant I had to put the project on hold."

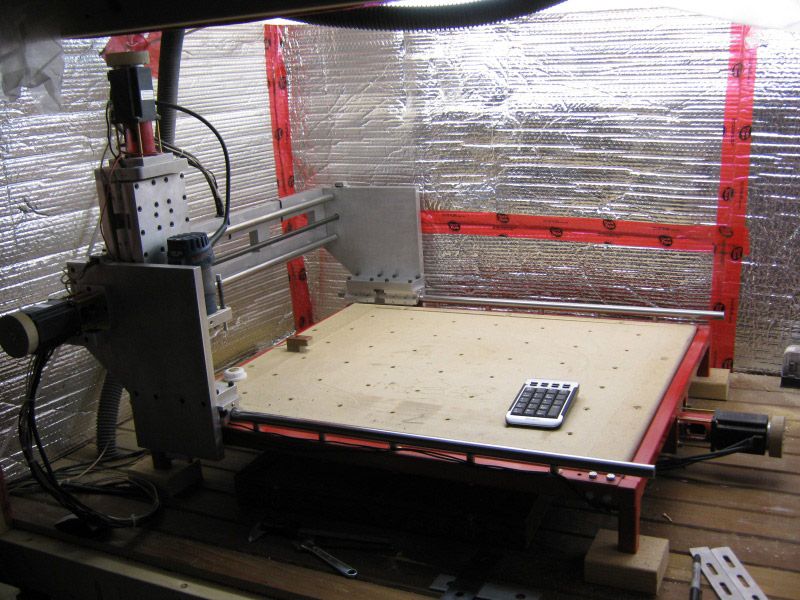

"About a year later I revisited the auction house and this time found a RF-32 Mill drill. I purchased it and put it beside my stagnant lathe until I had more time to work on them. In anticipation of continuing my rebuild I would often visit websites to learn more about lathes/mills, it was during this research that I discovered people were also building DIY CNC machines in their basements - I needed to know more! After further research I soon found CNCZone.com, the community helped point me in the right direction so I was able to start building my own CNC. I originally considered just buying a DIY CNC kit but I knew if I put my mind to it then I could build my own. Once my life had eased up and I found myself with some free time again this allowed me to put the workshop into full gear and finally finish the lathe and mill."

"Now that my other machines were complete I was ready to to build my own CNC. I convinced a friend to assist me with the build and luckily he was all for it. He got as far as building the base frame, bearing blocks and rails and I got all the electronics, motors and drivers together. Shortly after this the project went stagnant again, but it wasn't long before I ended up 'borrowing' the base from my friend and continued the build myself. I scrounged what ever else I could and decided to buy the rest of the material for the project."

"As the build was nearing completion I began to think about what software packages could help me drive my new equipment. For control software Mach3 is the number one contender for the home shop machinist, but when it came to choosing a CAD/CAM software package then that was a different story."

"As I'm just a hobbyist, I needed to find the most cost effective way to design and machine projects using my CNC. I tried many of the options out there, but after I discovered Vectric's VCarve Pro software I had a really hard time with any alternative options."

"From prior experience I knew how other CAD/CAM packages worked and I was able to compare the functionality available in VCarve Pro. I downloaded the free trial version and started to play, I knew there and then that this was the software that would help me develop my hobby further. VCarve Pro already makes me feel like an expert and when I look at what I have been able to create since purchasing it, I feel as though I have been able to produce professional results."

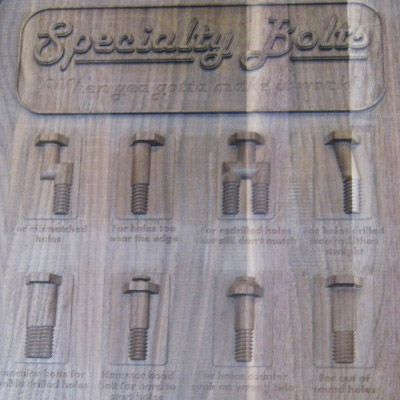

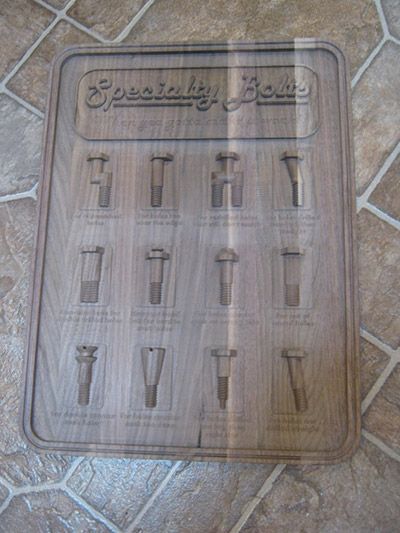

Chris has produced a variety of projects that you may have seen on the Vectric Forum, including a GeoCoin, Man Cave Sign and Mayan Calendar. The idea behind his latest, 'The Specialty Bolts' sign came after he rediscovered an old line drawing of the bolts at his work place. This drawing, coupled with his desire to start working in 3D, gave Chris enough of an excuse to take on the project. Chris goes on to explain how he utilized the artwork in a 3D modeling package along with Cut3D and VCarve Pro to design and machine the sign.

"I trained myself on a low cost engineering CAD package until I had enough knowledge to go ahead and create the bolt shapes. The finished models were exported as STL files and then these were imported into Vectric's Cut3D software to generate the necessary toolpaths. The Cut3D file was then saved and I imported the toolpaths into VCarve Pro and finished up the layout, adding the text and creating the additional toolpaths."

You can see a video Chris posted of his toolpath preview from VCarve Pro by following this YouTube link

"I created a few different versions of the design but finally came up with what you see below. All of the material I have used with my CNC up to this point has been MDF, but I found on this project it cut with less than desirable results. Based on this I decided to cut a sample in walnut and found the results were much cleaner, this is when I decided it was the right material for the project. After choosing the material I loaded up the toolpaths into Mach3 and setup the machine and the material limits. Once I double checked everything I was ready to run the toolpaths and in the end the entire machining time was over 14 hours."

"Overall the project turned out fantastic! I love seeing the expressions on people's faces when they see it. The whole thing has been a lot of fun to do and working with the Vectric software helps to make it an enjoyable experience."

Chris has already started work on his latest project, a custom clock, which is documented in his build log on the Vectric Forum - Click Here to follow the build. Chris's other projects can also be found on the Vectric Forum posted under his username 'Mogal'.

We would like to thank Chris for taking the time to talk to us and we look forward to seeing his future projects on the forum.

Vectric Ltd

Precision House

2 Arden Road

Alcester

B49 6HN

Registered in England Number 05382596

VAT Registration GB115123072

Privacy Policy |

Cookie Policy |

Terms and Conditions